Variations in forage quality and moisture begin in the field during the growing season, and variations in quality can become larger through harvest, storage and feeding techniques.

Research from Dann Bollinger, U.S. dairy specialist, DuPont Pioneer, found variation in dry matter, 24-hour neutral detergent fibre digestibility and starch of up to 8.9 percent, 13 percent and 10.8 percent, respectively, across a large corn silage bunk face.

During feeding, any discrepancy from the sample your nutritionist used to balance the ration can lead to even further variation in the nutrients being delivered.

Variance from the balanced ration can make production goals and finding solutions to herd health problems more difficult. Thanks to the collaboration of research and technology in the agriculture industry, new tools are available to help you deliver consistent forages – from seed to feed.

-

Seed: Variability in forages is one of the largest struggles for nutritionists and dairy farmers in achieving higher dry matter intake and delivering a consistent amount of nutrients.

This variability begins in the field from many sources such as hybrid selection, seeding rate, fertility, drainage and changes in soil types and organic matter.

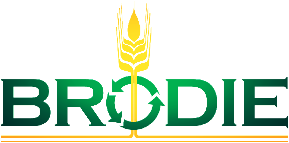

Knowing the locations of different soil types in a field can provide you and your agronomist the tools to correctly place corn hybrids, prescribe the most economic planting populations, adjust fertilizer and nitrogen rates as well as fine-tune nitrogen delivery timing.

Your local seed sales representative or agronomist may have a program available that can complete these prescriptions for you.

Many programs are compatible with a range of equipment technology, and prescription instructions can be loaded automatically into a tractor at planting or into sprayers and fertilizer applicators, which use GPS to alter application rates.

This not only improves yield potential but also ensures the maximum return per unit of input used.

As shown in Figure 1, advanced field management programs can come equipped with a personalized weather station located near your fields to track heat units, precipitation, humidity, wind speed and other weather factors to help with important in-season fertility and forage management decisions.

-

Harvest: The variability in silage quality is typically realized after harvest is complete and you have limited control over the corn silage quality you are about to feed for the next 12 months.

New near-infrared harvest technology can greatly assist with estimation based on physical appearance of the corn during harvest.

The near-infrared instrument attaches to self-propelled forage harvesters and takes in-field readings of the silage dry matter, protein, starch, neutral detergent fibre, VFA and ash.

By setting target corn silage values for starch percentage and neutral detergent fibre with your nutritionist prior to silage harvest, silage cutting height can be adjusted in the field to consistently achieve your desired starch and fibre percentages.

As an additional bonus, some near-infrared harvest instruments can be used 365 days a year, allowing you to check for any moisture and nutritional changes in your forages. This will help you consistently provide the right ration to your dairy cows.

-

Store: The target for optimizing homegrown forages is to minimize dry matter loss in storage and maximize dry matter intake at the feedbunk. In the past 30 years, there has been a significant growth in knowledge about the fermentation process of various silage crops.

Following the first generation of forage inoculants recommended for use on all crops, there emerged crop-specific inoculants as knowledge increased regarding the uniqueness of different silage crops.

For example, grass-legume crops have relatively low sugar, are wilted on the ground (increasing potential for ash contamination in silage) and have a naturally high pH buffering capacity. This contrasts to corn silage that has a lot of sugars yet are loaded with yeast.

For this reason, inoculants designed for corn typically do not do well on grass-legume silages. Finally, as silage face exposure has increased with larger and larger bunkers and drive-over piles, research has shown that half or more of the feed energy loss during storage occurs at feedout.

Forage inoculants containing Lactobacillus buchneri have become a standard in many operations to minimize nutrient loss and provide excellent bunk life to help keep feed fresh in the feedbunk.

Advanced inoculant products allow producers to gain by maximizing fermentation efficiency, improving bunk life and improving fibre digestibility – all of which combine to help producers maximize the forage content in the ration and help drive lower feed cost per unit of milk.

-

Feed: Nutrient variation occurring in the bunker or silo is only further complicated by any alterations that may occur in daily feed mixing and delivery.

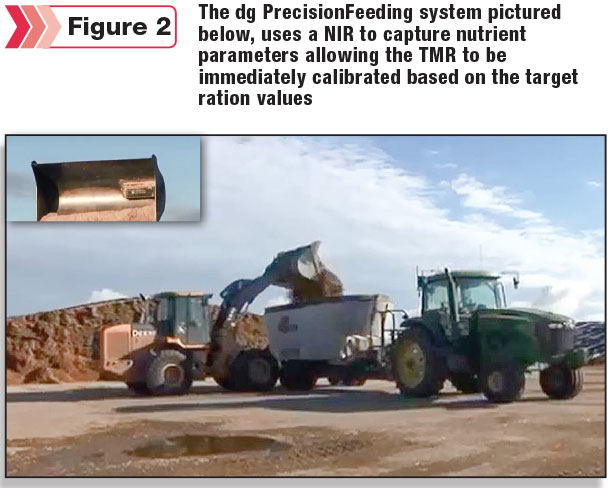

Near-infrared instruments are starting to become commercially available for use at feed delivery, allowing for real-time analysis of every bucket of feed dumped into the mixer wagon.

These units can be attached to a self-propelled cart, front loader and automated feeding systems. This allows for extremely consistent TMR delivery, instantly detecting changes in forage quality and helping ensure the same amount of nutrients are being delivered to your cows every feeding.

These emerging technologies entering the dairy world can help reduce input, labour and feed cost, improving herd health and your bottom line. Discuss these options with your farm’s agronomy and nutrition consultants to determine if these technologies fit your operation and how they might maximize returns for your dairy herd. PD

-

Ashley Hall

- Dairy Specialist – Western Ontario

- DuPont Pioneer

- Email Ashley Hall