What defines corn maturity?

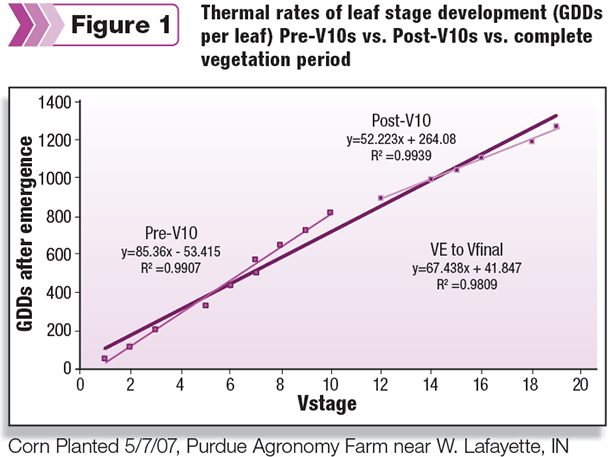

Let’s start at the beginning and look at what defines corn maturity. Very shortly, it’s the number of leaves a plant has on the stalk. In order to decrease maturity of a hybrid, corn breeders target less leaves on the plant when breeding for hybrids suited for western Canada. A typical hybrid may have 18 to 20 leaves, while an early maturity hybrid will only have 10 to 12 leaves. Typically, removal of one leaf amounts to around 60 growing degree days (GDDs), less needed as shown in Figure 1.

When producers are looking for corn hybrids for their operation, they should be aware of a few key points, including the length of time from planting to tassel and grain dry-down of the hybrid. The length of time from planting to tassel is different for each hybrid and will have a significant impact on the success a producer has harvesting their corn at the appropriate stage. Conversely, time between tassel and silage or grain harvest remains constant between hybrids, steady at 45 days from tassel to half milkline for silage and 55 to 60 days from tassel to blacklayer for grain.

Therefore, to help determine if a new corn product fits your area, compare its silk rating to a corn product you know and consider that earlier silking corn products generally move north of their adapted zone and more readily adapt to higher elevations. If moved too far north or up in elevation, late silking corn products may not reach physiological maturity before frost, or may have reduced yield potential if abnormally late silking exposes the crop to cooler temperatures during grain fill.

Should I choose a long-season hybrid to maximize digestibility?

It is important to choose a hybrid that fits the maturity zone. This will maximize silage tonnage, quality and fermentation dynamics. Planting hybrids that are excessively longer than the maturity zone results in high tonnage of biomass with minimal ear development.

Silage yield

Total ear development accounts for up to 60 percent of total tonnage produced, which is another reason to target good grain production in silage. Likewise, planting an excessively longer hybrid will impede proper grain development and the producer will sacrifice yield, not just quality of his silage.

Ensiling immature corn

The developing corn ear is largely responsible for lowering plant moisture, because typically grain has much lower moisture content compared with wetter stover plant parts.

Plant dry-down will be delayed, and producers will have to wait for one to two killing frosts to get the crop to dry down into the ensiling 65 percent moisture zone.

Harvesting the corn prior to a frost results in overly wet silage, where exudate will freely flow out from silos, increasing nutrient loss. A couple of killing frosts may not jeopardize the NDF digestibility (NDFD) quality of the stalk material, but the leaves are going to severely decline in NDFD once killed off by frost events.

Fibre digestibility

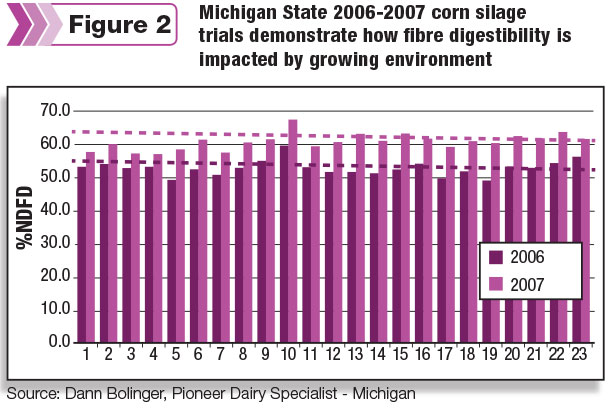

It is important to remember that fibre digestibility will be determined pre-silking, based on environmental conditions. The graph in Figure 2 shows that hybrids grown in a drought year (2007) had higher NDFD, compared with the same hybrids grown in a normal year (2006).

Therefore, whether the plant is a long-season or short-season plant, it results in the same digestibility given similar environmental conditions. In other words, the growing season will dominate what the fibre digestibility will be, with genetics only playing a small (3 to 4 percent) role in digestibility. It is important to note that digestibility of the stover does not decline as the plant matures, which is opposite to many forages, and only slightly declines once blacklayer is produced.

Sugar versus starch

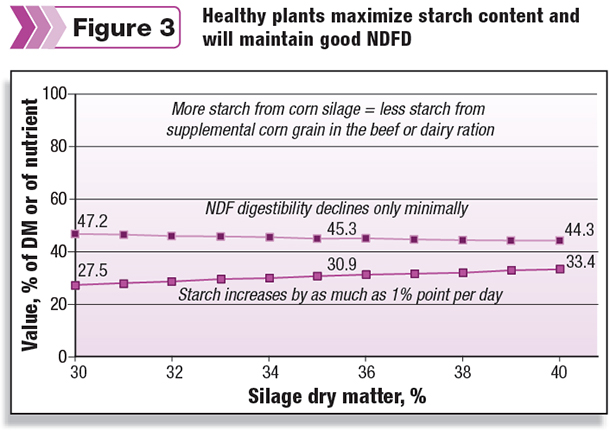

Corn is nature’s most efficient cereal crop for converting sugars from photosynthesis to storage vessels known as starch granules in the kernel. Although starch and sugar are both fast-release carbohydrates, one starch molecule is comprised of hundreds of sugar molecules. Therefore, high-starch corn silage will have more energy than high-sugar corn silage. The latter will have the energy available from the sugar concentration and minimal amount from any starch. However, half milkline corn silage will have the sugar energy, along with all of the energy from dense starch. Once the starch is exposed to amylase during the digestion process, it is converted back to sugars. Increased cattle productivity from high-quality corn silage for both beef and dairy operations is driven by the developing corn kernel and the fibre digestibility of the crop at this stage of harvest maturity. Figure 3 clearly shows that during desired corn silage harvest maturity, starch continues to accumulate in the plant while at the same time losing only minimal amounts of digestible fibre.

The goals of good silage

The goal of good silage is to put up silage at half to three-quarters milkline to maximize starch accumulation. An immature corn plant will have higher sugar content than a mature corn plant because it has not had time to convert the sugar to starch. A producer spends the same amount of money to grow, ensile and feed high-sugar corn silage as high-starch silage; however, high-sugar corn silage contradicts the reason we grow corn for silage in the first place.

In the end, harvesting silage at half milkline accomplishes two goals:

- Near maximum amount of starch, with the rest being residual sugars as the rapid carbohydrate source

- Near maximum NDFD that was determined during the vegetative stages of plant growth (irrelevant of length of hybrid)

In closing, growing excessively long-season hybrids will jeopardize silage quality by impacting fibre digestibility and minimizing grain development, thus reducing the energy and overall quality of the silage. Therefore, proper hybrid maturity selection is crucial when growing corn for silage or grain in northern environments in order to ensure producers are successful and have the best quality feed for their herd. PD

-

Breeanna Kelln

- Livestock Information Manager, Western Canada

- DuPont Pioneer