Whether producers are choosing robots as part of a new facility, or because of the benefits it offers for labour, time management, lifestyle, etc., the one comment I often hear is that the dairy’s purchased feed cost has gone up significantly from the more traditional one-group TMR they had been feeding before the switch to robots.

So the question is: Will your purchased feed costs go up if you make the switch to robotic milking?

The simple answer: Yes. Unless you are currently buying all your energy, protein and mineral needs in a complete feed, there is invariably going to be some level of increase to your purchased feed bill.

How much will depend on several factors: the type of traffic system you use with your robots, the type of feeds you are feeding in your robots and the energy and protein balance for your base partial mixed ration (PMR).

There are three main types of cow traffic systems when milking with robots: free-cow traffic, feed-first guided-cow traffic and milk-first guided-cow traffic. Each of these systems have their own positives and negatives that should be discussed with your prospective robot milking supplier as well as other robot producers.

The right system for you will be based on the robot you choose, your personal management style and your goals for the robotic milking system. That being said, there are different ways that milk cows can be fed in each of these traffic setups.

We will discuss these here and give you an idea of the differences in feed costs for each compared to a one-group TMR for a traditional non-robotic milking herd.

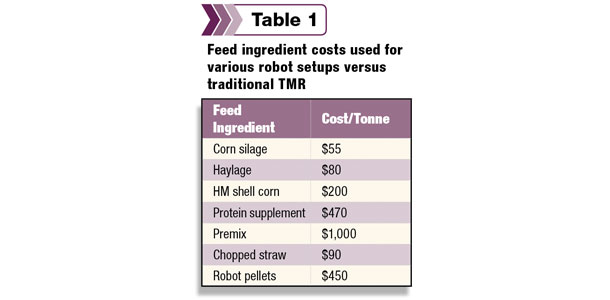

In our examples, we will use the same feed costs for our base ingredients that form the traditional TMR or the robot PMR. Table 1 gives an example of the feed costs used for our examples.

Obviously, these costs can change from farm to farm and week to week, but the point is that for each individual operation the input costs can remain the same for the feeding examples.

Let’s take a milking herd that is averaging 32 litres of milk with a 3.8 percent milkfat for our example. In a traditional one-group TMR feeding setup, we could have a TMR that is balanced for 35 litres of milk production.

This TMR would be fed with the goal of increasing milk production in the herd and finding a balance between meeting the needs of our high-producing cows while also making sure that late-lactation cows are not becoming overconditioned before dry-off.

Using our feed costs from Table 1, this ration would cost $5.99 per cow, per day to feed. Purchased feed costs are the protein mix and the vitamin/mineral premix and total $1.86 per cow per day. On a 100-cow dairy, this would equal $67,890 in purchased feed costs for the milk cows for one year.

In a milk-first guided-traffic design, cows are guided towards the milking robot on their way to the feedbunk if the robotic system deems the cow has milking permissions. Ideally, a cow makes eight to 12 trips to the feedbunk in 24 hours, allowing the robot to milk the cow multiple times.

In this system, the feed at the bunk is the motivation for cows to move through the barn. Using the same 32-litre milk example, the PMR in this system would be balanced at 33 litres of milk. This allows sufficient energy and protein for the cows to make milk and increase the chances of receiving milking permissions on their way to the feedbunk.

In milk-first systems, robot pellets will be fed at 1 to 3 kilograms per cow, per day in the robot. This serves mainly as a feed to occupy the cow while she is being milked. Robot pellets at an average of 1.5 kilograms for our herd would cost $0.68 per cow per day, while the protein and premix in the PMR would add an additional $1.78 per cow per day in purchased feed costs.

Combined purchased feed costs total $2.46 per cow per day in this example, while total ration cost is $6.13. On the same 100-cow dairy, purchased feed costs for the milk cows would be $89,790 for the year.

In a feed-first guided-traffic design, cows are allowed to freely access the feedbunk but must return through sort gates on their return to their resting area in order for the robot system to determine if the cow has milking permissions.

If the cow has permission, then she will be sorted towards the robot to be milked. In this system, the feedbunk is the main attractant for cows to move around the barn. Ideally, cows will move to the bunk eight to 12 times per day to feed, thus allowing the robot system to milk cows multiple times per day.

For our example herd, the PMR would be balanced at 30 litres of milk. Robot pellets in this system would be fed at 2 to 5 kilograms per cow per day in the robot to help boost milk yield of early lactation cows and to help encourage more traffic around the robotic system.

These pellets, at an average of 2.3 kilograms in our example, would cost $1.03 per cow per day. Additionally, the protein and mineral in the PMR would contribute $1.62 per cow per day in purchased feed costs.

Combined purchased feed costs in this example total $2.65 per cow per day while total ration cost is $6.21. On our 100-cow dairy, purchased feed costs for the milk cows totals $96,725 for one year.

In free-cow traffic systems, cows are permitted free access to both the feedbunk and the milking robots throughout the day. The robot determines if the cow has milking permissions and either milks the cow or refuses her.

In this system, the milk cow PMR is traditionally balanced at 7 kilograms below the herd average production. Therefore, in our example herd, we will have a PMR balanced for 25 litres of milk, while 2 to 7 kilograms of robot pellets are fed in the robotic milker.

The robot pellets act as the main attractant for cows in this system, with the opportunity for her to receive required energy every time she is milked, encouraging multiple visits and milkings.

Robot pellets fed at an average of 3.4 kilograms in our scenario would cost $1.53 per cow per day, while the protein and minerals in the base PMR totaling $1.45, bringing total purchased feed costs to $2.98 per cow per day. Total ration costs would be $6.39, while purchased feed for our milking herd would be $108,770 for the year.

Primarily because of the additional purchased energy feed that is required for the robotic milking system and its replacement of homegrown energy feeds included in the traditional one-group TMR, the purchased feed costs for each robot cow traffic system are higher than for the traditional TMR.

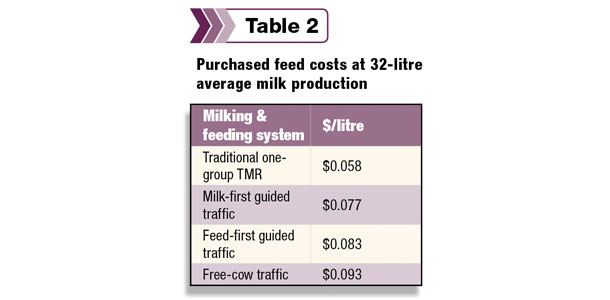

Purchased feed costs, calculated per litre of milk, for the above examples are shown in Table 2. This is partially offset, however, by a reduction in homegrown feed requirements so that total ration cost increased less than purchased feed cost for robotic milking in these examples.

These are common options for feeding in various robotic milking setups, but with robots offering the option of feeding multiple feed types, farmers are finding various ways to lower their feed bills while still maintaining their production and health goals.

Feeding their own homegrown high-moisture shell corn along with a higher-protein robot pellet is the most common, while others have made their own on-farm grain mixes using various grain and byproduct ingredients.

Straight feed byproducts or grains can be used as partial or whole replacement of robot pellets in some situations. In any of these scenarios, an added level of management is required by the producer to ensure the feed they are providing is fresh, palatable, consistent and flows well within the robotic feeding system.

When making the decision to buy a robotic milking system, there are many factors to consider before deciding which robot is the right one for you.

Anticipate higher purchased feed costs compared to a traditional TMR feeding system with homegrown corn or high-moisture cob meal. Feeding and feeding management should be some of those factors included in the decision process.

Every farm will be unique in how they feed and manage their cows, and deciding which option is the best for you will help in your decision-making process. PD

PHOTO

... with robots offering the option of feeding multiple feed types, farmers are finding various ways to lower their feed bills while still maintaining their production and health goals. Photo by Ray Merritt.

- Jeff Keunen

- Ruminant Nutritionist

- Grand Valley Fortifiers