Ensuring cows are bred soon after the voluntary waiting period and subsequent open cows rebred in a timely manner is critical to the profitability of a dairy operation. Heat detection is one of the key components in the management of dairy herds. A delay in breeding either at first or repeat services will increase the number of days open and extend calving intervals. The cost of poor heat detection adds up with a greater risk of culling and reduced milk production and is the real driver of higher replacement costs, all affecting your profitability.

Commonly, heat detection is performed by visual observation, but this is difficult because observation periods usually occur during feeding and milking when both the cows and observer are distracted. Most large dairy operations use tail chalk/paint and once-daily observation for heat detection, which is usually superior to visual observations, but still leaves room for improvement.

As a result of technical progress in monitoring cows with the use of computers, automated heat detection has become possible. In many studies, different traits have been analyzed for utilization in automated heat detection systems. The best results were found for detection using activity systems.

Results of heat detection efficiency and accuracy varied depending on the threshold value to determine when to declare high activity, the number of cows studied, housing and cow comfort, the method of time series analysis, and the number of days and time comparison for establishing a baseline of activity to determine when to declare high activity that should be associated with estrus.

Pedometry is not a new technology; it was first employed on dairy farms for heat detection about 25 years ago. Over this time span, numerous scientific studies have been published that have reported on various properties of pedometry, from environmental factors that affect heat detection and accuracy rates to the ideal timing of insemination.

Generally, pedometers are electronic devices that measure walking activity or steps. The device is located either on a hind or front leg. Most commercially available systems transfer the activity data during milking either by a walk-through portal or with a reader at each stall. For most systems the pedometer is also the milking parlor identification tag, so the device cannot be moved from the cow once confirmed pregnant, requiring a device for each cow.

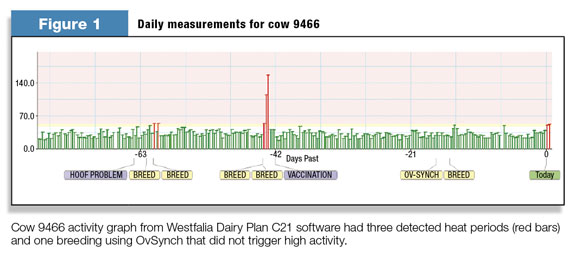

An example of the output from a Westfalia Dairy Plan C21 system is shown in Figure 1 . This herd is milked three times a day, thus there are 21 bars every seven days (interval between two horizontal lines is seven days), and the variation in activity above the threshold is evident by the variation in the number and level of activity events.

Activity systems that measure head movements associated with estrus expression are the newest generation of heat detection systems. Three systems are presently commercially available. All systems include three basic components: monitors, base station and a computer or control box.

There are various combinations of base stations, amplifiers, antennae and portal readers to get the signal from cows to the computer/control box. Necessary equipment is dependent upon each specific system. Monitors are motion-sensing devices attached to a neck collar. All monitors collect data continuously (24 hours a day and seven days a week).

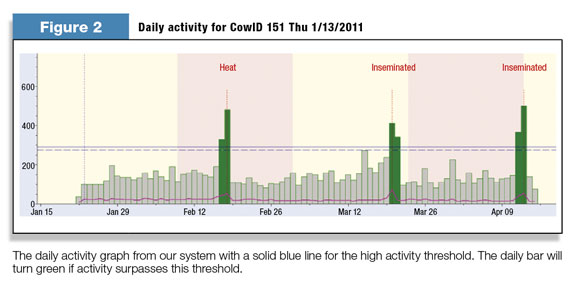

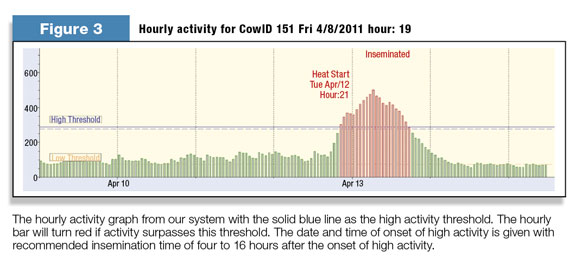

Examples for daily and hourly activity from one of the systems are shown in Figure 2 and Figure 3 , respectively.

In general, the software examines data mathematically to identify cows with high or low activity. Again, high or low is a reflection of the baseline activity for each cow and routine herd movement. Results are available for individual cows and lead to three possible conclusions: cows in heat, cows that need examination for other sign of estrus or no action needed.

In an initial study we conducted, conception rates from 4,126 services were recorded from 19 herds located in eight states. The results of the study were consistent with similar studies based on observed mounting activity wherein optimum conception rates are obtained at A.I. intervals proximal to 12 hours after detected estrus (high activity), with shorter intervals appearing to be less compromising to conception rates than longer intervals.

The major limiting factor with pedometers and activity systems are the type and level of activity used in the mathematical equations employed to determine the detection and accuracy rates. It is well known that individual cows differ significantly in the amount of activity expressed during estrus even under the same farm conditions.

All systems determine an individual baseline of activity used to compare current activity to decide if the real-time information is above a preset threshold. This is where the mathematical equations become important to declare the cow in heat. High activity should be used as an excellent secondary indicator of estrus, and when combined with a previous insemination interval of 17 to 24 days or other secondary signs of heat, makes the decision to breed or not to breed easier.

Breeding cows solely on the output of pedometry or activity will usually result in overbreeding cows if the threshold is set for high detection rates. An adjustment in the threshold level requires a balance between high detection rates and low error rates. All systems have a default threshold level based on the research for that system.

After a period of time, threshold levels should be adjusted according to specific farm conditions; size of the pens or corrals; number of milkings per day; walking distance from barn to parlor; and other activities. The recording of cows not detected by the system and cows detected but not believed to actually be in heat is important information for establishing an accuracy threshold that should optimize detection rates and minimize error rates.

The basic training of new users and continuous support of farm personnel are important to maximize the benefits of activity or pedometry systems. Human skill and experience to differentiate a “true” peak of activity caused by a cow in heat from a “false” peak in activity due to other causes for an increase in activity is closely related to improved reproductive performance, and there is a learning curve with all systems.

Getting cows pregnant is complex and requires a comprehensive approach. Cows that are not inseminated when in estrus will not become pregnant. Reproductive success is measured by confirmed pregnancies. The first response that is noticed by producers once an activity system is installed is usually increased palpation pregnancy rates or more pregnant cows at herd checks.

With the growing public interest in the living conditions of food-producing animals, and the growing objection to any unnecessary use of pharmaceuticals, activity systems have the potential to be useful tools in the reproductive management of dairy herds. There are a growing number of producers who have purchased and use an activity system as a vital component of their reproductive management program.

The real proof on how a system improves the reproductive performance is visiting dairy operations or questioning producers who use a system to learn from their experiences. PD

References omitted due to space but are available upon request to editor@progressivedairy.com .

-

Ray Nebel

- Reproductive Specialist

- Select Sires

- Email Ray Nebel