The chance of getting a cow pregnant is influenced by a variety of factors, which can make understanding and controlling pregnancy tricky in a sea full of Bessies.

In working with automatic milking systems, producers are able to combine several sensor data points for more accurate heat detection, including activity, rumination and robot visit behaviour.

Utilizing AAM

Automated activity monitoring (AAM) systems provide accuracy for 24-7 monitoring of cow reproductive and health status.

This proves useful for producers because most silent heats occur at night, and high-producing cows tend to have short heat periods that are not easily picked up visually.

With AAM, producers also obtain indicators of individual animal health. For example, a sudden drop in rumination activity, compared to a cow’s normal rumination time, indicates that a cow is either in heat or ill.

Some systems used with particular automatic milking systems utilize tags that include an acceleration sensor, specially tuned rumination microphone, a microprocessor and memory.

The tag records a general activity index and analyzes the vocal signals to calculate rumination time. Then the tag creates an activity index, allowing you to inseminate at the correct time.

Therefore, reproduction is optimized, calving interval is minimized and semen costs are significantly reduced.

In addition, automatic heat detection eliminates the need for widespread use of Ovsynch programs, a commonly used hormone treatment protocol to synchronize ovulation so cows can be inseminated at a specific time.

By reducing the need for timed breeding, producers experience cost savings not only on hormones but also the additional labour necessary for injections.

AAM vs. synchronized breeding programs

Reducing the use of an Ovsynch program saves on the cost, as well as on time related to finding and treating cows.

Hormone injections are still useful, but with the help of new technologies, such as AAM, producers can improve heat detection and herd health while lowering costs and reducing labour.

A field study conducted by the University of Guelph comparing the reproductive performance of systems using AAM to synchronized breeding programs revealed the following results: Activity-based heat detection works equally well and, at times, more effectively than synchronized breeding programs.

Using the same identification and cow activity measurement tags as those used in milking robots, two out of three herds showed better conception rates, fewer days to first service and decreased days to pregnancy.

The results of the study are published in the Journal of Dairy Science.

AAM results and program adaptation

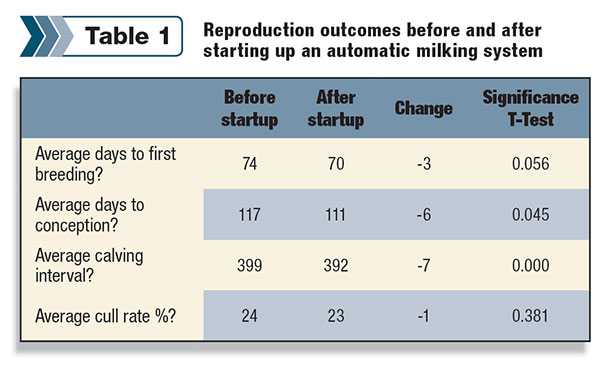

In a recent survey conducted by Lely North America, robotic milking customers with a startup occurring between 2008 and 2011 saw reproduction outcomes improve significantly in the first year of automatic milking systems (Table 1).

Dairies that transition to robotic milking often opt for automatic heat detection systems, using identification and cow activity measurement tags.

In the early stages of transitioning to robotic milkers, many producers continue to use Ovsynch programs after discovering that the cow is unable to have a natural heat cycle.

Producers then adapt their timed-breeding program to only those cows not showing a natural heat.

One North American dairy, Kiefland Holsteins, LLC, changed the breeding program on their farm after the introduction of a robotic milking system to their operation in April 2011.

Prior to 2008, the farm observed heats and bred cows using minimal Ovsynch programs, resulting in a pregnancy rate ranging from 15 to 16 percent.

Between 2008 and April 2011, before the installation of robotic milkers, Kiefland had a technician chalk cows with a full Presynch-Ovsynch program, a protocol that “pre-synchronized” cows and saw pregnancy rates increase up to 19 percent.

“This change happened because we had better heat detection and a strict injection program,” says Chad Kieffer, owner and operator.

“Since the introduction of the robots with the automated activity monitoring, our pregnancy rates have increased once again to 25 percent and did not drop last summer.”

On the farm, cows at 35 to 42 days in milk (DIM) receive their first prostaglandin injection but are not bred at that time should the cow show heat.

Two weeks later, cows get a second prostaglandin injection and if they come into heat, they are bred. All heats are recorded, and if a cow shows a heat at any time during this period, they will not be enrolled into Ovsynch until 90 DIM, if not bred.

“We are trying to take full advantage of the activity system with this change,” Chad says. “As a result, we will keep saving more money on injections and continue to see more natural standing heats.”

Heat detection and optimum breeding times are key factors for reproductive success. By using activity and rumination monitoring, farmers are able to collect information and find cows in heat even when they are away from the barn – and use this to improve reproduction results on the farm.

Shorter calving intervals, reduced use of hormones and fewer straws of semen all result in lower overall reproduction costs and higher profit. PD

Dr. Sara McBurney is a veterinarian working in Farm Management Support for Lely North America in Canada.

References omitted due to space but are available upon request. Click here to email an editor.

PHOTO

Activity-based heat detection works equally well and, at times, more effectively than synchronized breeding programs. Photo courtesy of Lely North America.

Sara McBurney

Veterinarian

Farm Management Support

Lely North America in Canada