It’s been identified the value of a proper ventilation system is to prevent heat stress from occurring.

The Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA) identifies a three-step approach that states, “When ventilation cannot handle the heat load, supply supplemental cooling over the cows.”

Circulation fans can increase cows’ convective cooling rate during the summer season and become invaluable to the convection process of cooling cows.

There are various circulation fan options available to dairy producers that can provide value, if they are utilized properly.

Understanding the limits and capabilities of each fan style is helpful to identify the proper technology for the application. It is also important to note that not all fans are the same; the brand, model, size, etc., can all greatly affect performance.

Panel or basket fans

Panel or basket style fans are well known throughout the industry for their low capital investment and higher velocity air speeds.

This style of circulation fan provides dairy producers with the necessary air movement for the summer cooling season; however, the high operational costs can eat away at the bottom line quickly.

This style of fan can also be loud, primarily due to the large quantity of fans required to cover an entire dairy operation (as this fan produces a very focused flow of air). Panel or basket fans are ideal for tight spaces.

Directional fans

This style of fan has become more popular in the U.S., as it blends both high velocity and larger coverage areas. The capital investment per fan is much higher than traditional panel or basket style fans, but the requirement of less quantity can offset the overall capital investment cost.

High operational costs and loud decibel levels limit the effectiveness directional fans can provide to the Canadian dairy producer. Directional fans are ideal in larger spaces that require a focused stream of air in a certain location.

High volume low speed (HVLS) fans

Since the late 1990s when HVLS fans were introduced, they’ve been recognized for their low operational cost, high coverage area and low noise level.

Outdated case studies from 2002 identify that HVLS fans produce lower air velocities, however, new technological blade designs and proper fan sizing and placement offset those limitations.

While HVLS fans also have a higher capital investment per fan, the investment in circulation fans for the entire project can be equal to or less than panel fans or directional fans.

HVLS fans can also provide year-round benefits (not just summer cooling). HVLS fans are ideal in large, open spaces.

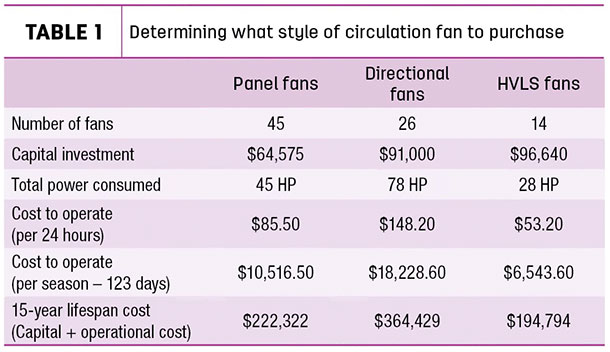

Comparing costs

When determining what style of circulation fan to purchase, there are several factors to identify. While performance should be the top priority, let’s first examine the cost to purchase and operate over a 15-year period.

In the chart below, electrical costs are based on 2017 Ontario rates; we’ve assumed there are no increases in electrical costs over the 15-year period (Table 1).

It is also assumed fans run at full speed for 123 days per year. Installation, maintenance and repair estimates have been omitted for simplicity purposes.

Understanding airflow

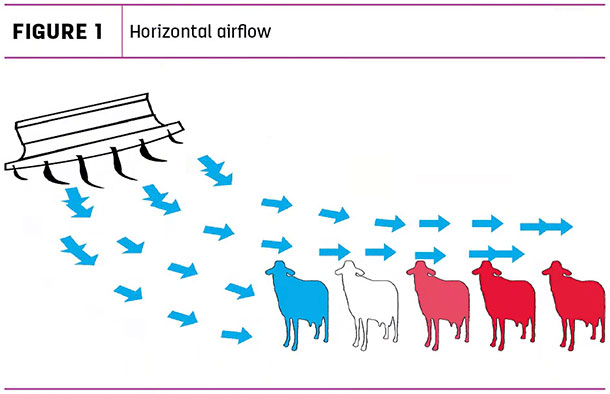

It is very common to consider velocity as the primary performance indicator of a circulation fan, as the greater the air speed, the greater the cooling capability.

However, it is also important to identify how much area that same fan is covering and how the airflow is affected by obstructions.

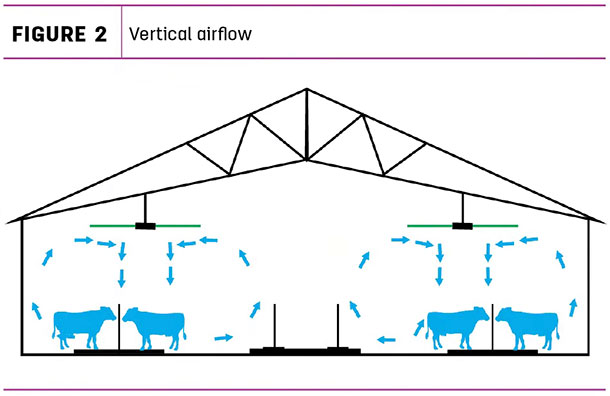

Consider that the directional fan and panel or basket fan push air horizontally (Figure 1) while the HVLS fan pushes air vertically (Figure 2).

Pushing air through or around objects becomes increasingly difficult with horizontal airflow, requiring more and more fans to provide full coverage.

Making the decision

The first step is to assess the space and identify goals and objectives for the circulation fans. Then discuss the circulation fans with your ventilation provider to ensure the air movement inside the space will not depress the performance of your ventilation system.

Finally, contact the manufacturer of the circulation fans and have them work to design a cooling system that meets and exceeds the goals and objectives previously identified.

Don’t hesitate to ask them to adhere to a budget while meeting your goals and objectives.

It is unlikely that one technology will provide the best solution for the dairy operation. In most cases, a blend of the various circulation fan technologies will result in the best overall solution to cooling.

Larger fans focused directly above the cows in the open spaces, with smaller fans focused directly onto the cows in more confined areas, is likely the most efficient and effective solution.

Utilizing the pros and limiting the cons of each circulation fan technology will maximize the results from the investment. ![]()

Photos courtesy of Enviro-North Systems Limited.

Dean Wood is a sales manager with Envira-North Systems Limited. Email Dean Wood.