We know cows are most comfortable at temperatures in the range of -5°C to 15°C. However, in summer, it is impossible to get temperatures to this optimum range. What could we gain if we could get it much closer?

“I believe the biggest benefit is any time you can drop the temperature in the barn during the warmer months, let’s say when temps reach above 20°C outside, the cows’ dry matter intake will not drop as much,” says Terry Lebold, Lebold Farms LTD.

“Therefore, it will have less effect on milk production, which is what we noticed last summer (after installing cooling cells).”

Evaporative cooling begins with tunnel ventilation, which itself is a good option for cooling cows, especially in tiestall barns. However, tunnel ventilation is limited by the outside temperature.

In order to tunnel ventilate a barn, we need to consider several variables. First we need to determine the amount of air we need to move.

As a basis, we are trying to move air at a speed of 300 feet per minute over the cows. To calculate this, we use the formula of (width x height) x 300 FPM = cubic feet per minute required to cool cows.

We then calculate how many fans it will take to move the air required. For example, a barn with a width of 80 feet and a ceiling height of 10 feet would require (80 x 10) = 800 x 300 FPM = 240,000 CFM.

A good-quality 50-inch tunnel fan will move about 26,000 CFM, so in order to cool this barn sufficiently, we would need at least nine fans.

Where many tunnel systems fail is inadequate inlet openings to provide air for the fans. As a rule, a 50-inch fan requires 50 square feet of inlet to operate properly.

For our example barn, we would require a total inlet area of 450 square feet. A six-foot opening the width of the barn would work well, especially considering what opening we lose to framing, etc.

Adding cooling cells to tunnel ventilation can make a significant difference for cooling. In this system, cooling cells are installed in the space of the inlets.

These cells consist of waxed paper honeycomb pads. The pads are held in place with an upper header and a bottom trough with water reservoir.

Water is pumped through the header and dispersed over the pads through a distribution pipe with holes in it. This water flows through the pads back to the trough below and is continually circulated.

Fresh water is added as needed by means of a float system. As air is pulled through the cells by the fans, it picks up the moisture, which evaporates. That evaporation cools the air traveling through the barn.

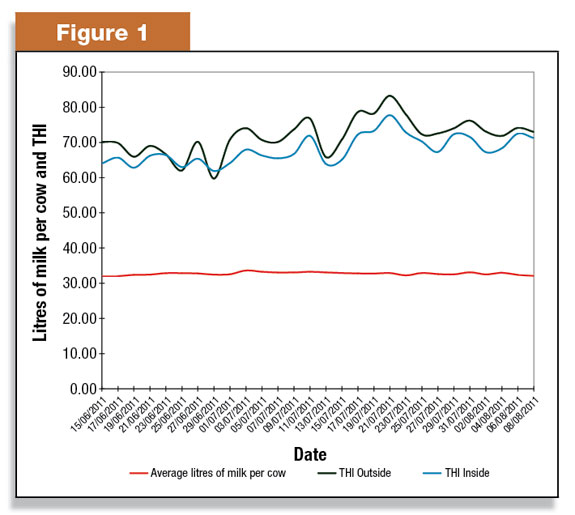

In the summer of 2011, Harold House and Dr. Neil Anderson from OMAFRA recorded data from Lebold Farms near Wellesley, Ontario.

This farm is using cooling cells along with tunnel ventilation. Time, temperature and humidity were continually recorded on the outside of the barn and at four different locations inside the barn with Hobo data recorders.

This barn is an older bank barn with four rows (two head-to-head) of really productive Holsteins. The inlet for the tunnel ventilation is installed in the mow on the east side of the barn.

This opening is five feet high by 70 feet wide. The cooling cells completely fill the opening of the inlet. A manually operated curtain is installed on the outside of the barn to protect the cells in winter. There are four 48-inch fans and two 50-inch fans installed on the west side of the barn.

As this was an informal experiment, the results of the data were just considered for information purposes and not considered conclusive.

What was found is that the humidity in the barn was typically higher than outside of the barn.

What was found is that the humidity in the barn was typically higher than outside of the barn.

This was true whether or not the cooling cell system was running, and can be explained with the fact that 80 cows were exhaling highly humid air. However, the temperature averaged 8ºC cooler inside than out. (Figure 1)

“The extra two 50-inch fans helped move more air through the barn, along with the cool cell cooling the air,” Lebold says.

“The temp was around 8ºC cooler inside the barn than out … which kept us and the cows a lot more comfortable.”

Once the calculations were made the THI (temperature, humidity index) was slightly lower in the barn than outside on most days. Although the THI levels indicated the cows still should be experiencing a “mild heat stress,” the cows did not appear to be affected.

The cows actually responded with slightly increased production through the heat of the summer. The customers also responded with appreciation to the cool barn.

“Any little extra thing you can do to make a cow more comfortable, you will reap the benefits not only in production but reproduction,” Lebold says. PD

PHOTOS:

TOP: Fans on the west end of the barn pull moist air through the cooling cells on the east end of the barn.

BOTTOM: Cooling cells are installed in the space of the inlets. These cells consist of waxed paper honeycomb pads. Water is dispersed over the pads through a distribution pipe with holes in it. Photos courtesy of Kevin Kraemer.