Ensiling forages, an age-old process, comes with both unavoidable and avoidable losses of nutrients. With corn at $6 per bushel and soy beans at $12 per bushel, the market value of corn silage based on its nutrient content is in excess of $70 per ton as fed or $200 per ton dry matter for a 35 percent dry matter crop – we clearly need to pay closer attention to the avoidable losses.

Avoidable on-farm shrink or dry matter losses in the ensilage process can have significant financial impact on the bottom line. For example, 1,000 tons of bunk silage at 35 percent dry matter with a 10 percent dry matter reduction overall will lose 35 tons of silage dry matter.

This lost feed is conservatively worth more than $7,000 (35 x $200). This loss of dry matter and nutrients from corn silage has to be made up from other sources. Even worse, it is the very digestible fraction that is lost (sugars, low molecular weight polysaccharides, volatile fatty acids and lactic acid), so the silage does not feed as well and even more expensive grain has to be fed to maintain production.

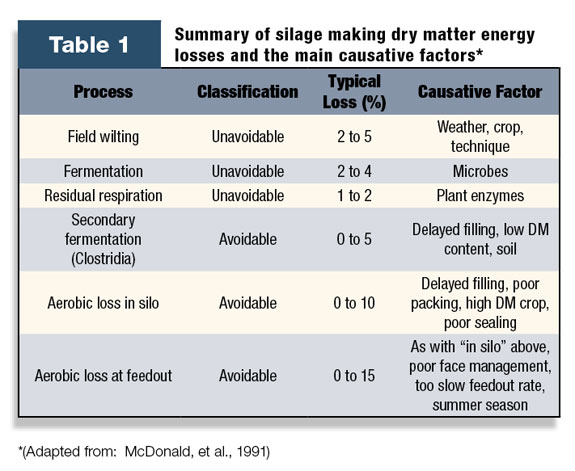

There are many sources of dry matter loss in the ensilage process, summarized in Table 1 .

Some of these are unavoidable even with modern silage-making practices but, by far, the largest potential source of dry matter losses are related to aerobic deterioration, and these need to be managed to avoid high losses during storage and feedout.

While many dairy farms use an effective inoculant to promote a good front-end homolactic fermentation, most are losing highly valuable digestible dry matter from the silo (bunk, pile, bag bale or tower) once the product is exposed to air (oxygen) and feedout begins.

This process of aerobic deterioration is exacerbated by warmer temperatures, especially in the summer. Well-fermented crops with low terminal pH’s and high lactic acid contents that were cool in winter are then prone to heating and aerobic instability at the bunk face, in drop piles and in TMR’s. Unless active management decisions are taken, high financial losses are imminent.

The wild yeast content of crops for ensilage

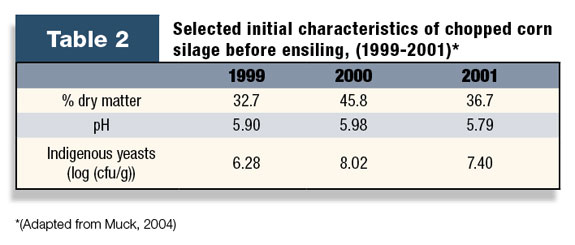

A starting point for understanding aerobic instability is the indigenous (wild), microbial profile of crops taken for ensilage. A typical example is shown in Table 2 for corn silage crops in Wisconsin sampled over three years prior to ensilage.

Although we cannot see them with the naked eye, every gram (0.002 pounds) of standing forage contains anywhere from 10,000 to 100,000,000 colony forming units (CFU) of indigenous (spoilage) yeasts.

From Table 2 it can be noted that a stressed crop, taken too late, has high wild yeast counts (e.g., year 2000).

These wild spoilage yeasts, an occupational hazard of the silage storage and feedout processes, were first noted in 1932. The role of wild spoilage yeasts in the aerobic deterioration of ensiled crops became increasingly understood through the period of 1964 to 1990.

Wild yeasts belong to the Fungi kingdom (as do molds) (moulds) but, unlike molds, wild spoilage yeasts are nonpathogenic and are not known to produce toxic secondary metabolites. They are predominantly aerobic, meaning they require oxygen to grow.

This means once the packing and sealing process is complete and anaerobic conditions are achieved in the silage bunk, bag or tower, wild spoilage yeasts inside the ensiled crop will be dormant and inactive. Wild yeasts can also be found in equally large numbers on small-grain silage crops, alfalfa and grass silages.

There is a wide range of wild spoilage yeasts represented in standing forages, but those of main concern are the lactic acid fermenting species of Candida, Hensenula and Pichia .

Once exposed to oxygen (through opening the silo or bag), these fermentative spoilage yeasts can use the lactic acid in the silage as an energy source, generating heat, carbon dioxide gas and water, almost literally burning up dry matter unless preventative measures are taken.

In warmer temperatures (65°F plus) (18°C), the spoilage yeast population can double every two hours, causing heating and local pH increases, allowing aerobic spoilage by molds (moulds) and bacteria, plus massive digestible dry matter loss. Typical yeast spoilage problems can be identified at the feedout face using two silage probes, one at three-foot depth and the other just six inches.

After 10 seconds the temperatures can be compared – as seen in the photo below. In this example, the heating due to spoilage yeasts is evident with a 35°F (20°C) increase near the surface compared to further back in the bunk.

In the summer, the yeast spoilage challenge increases and cow performance can be greatly compromised. The unstable silage or haylage may only be stable for a few hours either on the face or in the drop-down pile before making the TMR. Once unstable forages are mixed in the TMR, spoilage yeasts have more nutrients and more time to multiply, even in a 2x mixing operation.

The keeping quality of the TMR is compromised, transition cows are challenged and either milk production or milk fat is reduced. In studies with spoiled high-moisture shell corn added to a TMR, average daily milk yield was reduced by three pounds per cow within 14 days.

While the farm can resort to adding TMR stabilizing products to try to keep the feed stable, these do not address the spoilage yeast load in the parent forages, nor the dry matter losses caused in the silage itself. Furthermore, the TMR stabilizers are not cheap at the recommended application rates, costing in the range of 15-20 cents per milk cow daily.

Taking control

A greater financial return on converting silage crops to milk can be achieved with a more comprehensive forage plan that targets reduced dry matter losses from field to feedout. Key steps are detailed below:

- Cut at the right growth stage and target dry matter range for the crop.

- Short but effective wilting periods; haylage in a day.

- At chopping use a U.S. university-researched and industry-proven inoculant combination that contains the strain effective rate for Lactobacillus buchneri (FDA-reviewed claim for use at 400,000 CFU per gram on silage, 600,000 CFU per gram on high-moisture corn). This will generate acetic acid to control the spoilage yeasts and keep the product cool and stable at point of feeding.

- Pack silos quickly and ensure a packing density of no less than 16 pounds of forage dry matter per cubic foot.

- Seal effectively all over – sides, top and at the front toe.

- Once bunk or bag is open, move through it quickly to minimize face exposure to air (six to 12 inches in cool weather, 12 to 18 inches in summer with smaller faces exposed).

- Do not move top sheet and tires back too far at any one time.

- Keep face smooth with dexterous use of loader bucket – no lifting to let air in. Investment in silage defacer?

- Minimize time between taking down face and mixing in the TMR; do not pile ahead too much.

A good silage-making plan to control aerobic spoilage will include an effective silage inoculant based on a proven L. buchneri strain at the effective dose level. This is the cost-effective way to address the ongoing challenge of indigenous aerobic spoilage yeasts on silage heating, associated dry matter loss and depressed milk component yield.

By actively managing the entire ensiling process, you can keep that $7,000 of avoidable loss in your pocket. Definitely a case where prevention pays! PD

Co-author Bob Charley is employed as a forage products manager at Lallemand Animal Nutrition .

Click here to email an editor for references which have been omitted due to space.

PHOTO: Temperature probes indicating heating and yeast activity on the silo face.

-

Tony Hall

- Dairy Technical Services Manager

- Lallemand Animal Nutrition

- Email Tony Hall