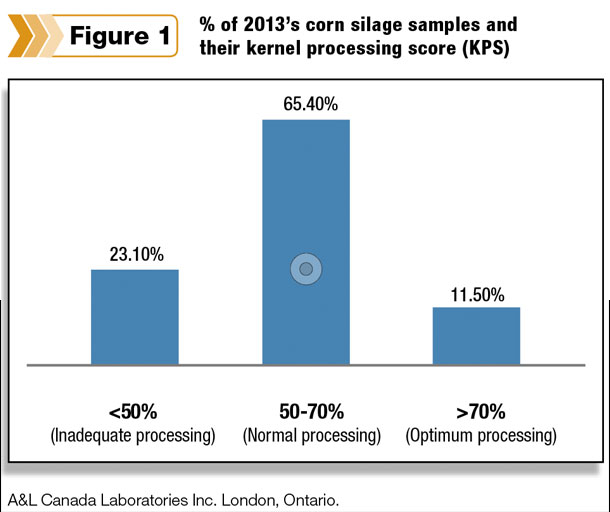

Figure 1 summarizes the kernel-processing scores (KPS) A&L Canada Laboratories Inc. found on more than 200 corn silage samples from the 2013 harvest. Although many people have kernel processors on their harvesters, it seems there is definitely room for improvement on kernel damage.

Dairy producers usually become more aware of the cost of lost corn particles in manure during years of high corn grain prices. Improperly processed corn kernels passing into manure may be more common in recent years due to corn growers’ selection of hybrids that will maximize starch yield.

Hybrids with high late-season plant health traits continue to deposit about 1 percent starch in the kernel for every 1 percent drop in whole-plant moisture as the crop enters into the maturity stage for silage harvest.

Therefore, the decision to harvest the crop at 63 to 65 percent moisture should produce approximately 5 percentage points more starch than traditional silage harvested at 68 to 70 percent moisture.

Ensuring that good kernel processing occurs during harvest starts several weeks prior to harvest by keeping the entire chopper in good condition, especially the chopper knives and the roller mill.

Nicked knives and worn shear bars should be replaced and the roller mill checked for wear on the teeth. Sometimes, only certain sections of the roller mill are worn, which creates a gap for the kernels to pass through without being processed. Replace rollers if they show signs of wear.

The integrity of the working parts is contingent on types of soil and other environmental factors. Corn grown on sandy soil, where wind is quite common, will cause more wear and tear on the moving parts.

After completing the inspection of the chopper head and roller mill, check the gap setting between the rollers: It should be 1 to 2 millimeters to ensure it cracks all the kernels. An easy tool to use is a dime (1.2 mm wide): If there is a lot of excess space between the rolls and the dime, tighten the gap.

Next, set the theoretical length of cut (TLC) at three-quarter inch, which is longer than the typical three-eighths to one-half inch TLC settings for non-processed corn silage. Processed corn silage requires a longer chop length to ensure sufficient particle length for ideal packing and fermentation in the silo.

It also provides cows with long enough particles that contain effective fibre for cud chewing and rumination. The feed roll speed is what determines chop length; speeding up the feed rolls produces a longer chop length.

All brands of harvesters (with processors) in good working condition can achieve well-processed corn silage, provided attention is given to the nature of the crop being harvested.

The grain-to-stover ratio of the crop impacts how much grain is going through the roller mill. The higher the grain content, the greater the need for more aggressive processing. Sometimes that means high-starch corn silages going through roller mills with a 1-millimeter to 2-millimeter gap may need a shorter TLC.

Harvest moisture also impacts kernel processing. A TLC rule of thumb to remember is that as you harvest dryer corn, decrease the TLC setting.

This may lower effective fibre but will ensure adequate packing of the dryer forage in the silo. Slowing down feed rolls causes less forage to be pushed through the chopper drum, resulting in a shorter chop length. The end result is a lower tonnes-per-hour chopper capacity that requires longer time to chop and adequately process the crop.

If feed roll and roller mill adjustments are not producing expected kernel-processing results, then inspect the differential speed of the roller mill. Corn silage processing involves having the upper roller running faster than the lower roller. Ten to 15 percent differential speeds are quite common among the various manufacturers.

When processing expectations are not being met, installing a smaller sprocket on the upper roll will result in differential speeds in excess of 20 percent. Some manufacturers who have responded to the needs of the dairyman have engineered roller mills to accommodate a 30 to 50 percent differential speed.

Of course, with all the above-mentioned guidelines, it is always best to refer back to the manufacturer’s guidelines to obtain specific information for adjustment settings.

A field-monitoring system during harvest needs to be established for determining the degree of kernel processing. Loads of forage coming to the storage structure can be inspected for kernel damage by a driver (not the person packing, if it is a bunk).

The chopper operator must be notified if adjustments are required to improve the degree of processing. Processing effectiveness may change from field to field and from day to day, so it is very important to monitor kernel processing throughout the entire silage harvest.

During harvest, samples should be checked at least once daily and whenever the chopper operator switches from one field to the next. In some cases, producers will inspect every load coming to the silo for the degree of processing.

A quick and simple on-farm technique to check degree of processing involves collecting a 1-litre (32-ounce) cup of chopped forage for field analysis.

Then spread out the collected sample on clean ground and manually sift through the entire sample, counting all kernels that are half or larger kernels. A nick is not enough; the kernels need to be completely fractured.

While this is a qualitative observation, a recommended guideline is that no more than two whole or half kernels should be counted per sample. The actual kernel number can be agreed upon by the dairyman and chopper operator; however, in all cases the count should never exceed a total of four half or whole kernels.

A field test was conducted by a dairy specialist in Michigan to compare the 1-litre technique to a commercial laboratory test that determines the percentage of starch from a dried sample that will pass through a 4.75-millimeter screen and is thereby considered highly digestible starch by cattle.

The correlation was quite strong at R2 = 0.80, and data revealed that having a kernel count of four or less will produce an ideal 70 percent KP score. The interpretation guidelines for the laboratory system are: less than 50 percent is inadequate, 50 to 70 percent is normal, and 70 percent is optimum.

Most dairy operations pay a great deal of attention to their business management decisions that aim to produce milk in the most efficient manner and at the highest level of profitability.

If a dairy operation feeding corn silage at 4 kilograms or 9 pounds dry matter per cow per day (at 35 percent starch and corn at $4.50 per bushel) could improve its KPS from 50 percent to 70 percent, it would achieve a grain savings of $0.08 per cow per day.

This is because at 50 percent KPS, less starch is available to be digested by the cows. Therefore, additional grain needs to be added to the ration to meet requirements. Achieving a 70 percent KPS permits supplemental grain reduction in the ration and thus results in a ration cost savings.

In conclusion, it makes good business sense that every dairy operation inspects the kernel processor and chopper settings before harvesting to obtain well-processed high-quality corn silage for maximum milk production. PD

- Martina Pfister

- Dairy Specialist

- DuPont Pioneer