When we think of palm trees, we usually think of sandy beaches and coconuts. Though fig- or coconut-bearing palm trees are generally the most recognizable, I am talking about the African oil palm (Elaeis guineensis), one of the most important commodity crops in Malaysia and Indonesia.

The African oil palm is a unique palm tree due to its contribution to the world oil crop, accounting for approximately 36 percent of the world oil production. The oil palm can produce up to 4 tons of oil per acre per year.

Palm oil is extracted from the fruit of the trees, which grow in bunches ranging from 20 to 80 pounds per bunch and can contain up to 3,000 individual fruitlets per bunch.

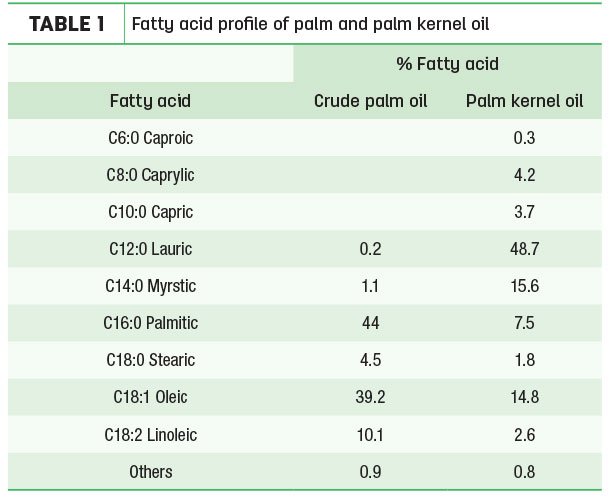

The fruit is made up of an outer layer (exocarp), contains an orange fleshy pulp (mesocarp) and has a nut containing a kernel. Palm fruit mesocarp gets its orange color from high levels of carotenoids such as beta carotene and is about 49 percent oil, whereas the kernel is white and contains high levels of oil with a very different fatty acid profile than mesocarp (Table 1).

Harvesting and processing

Palm fruit processing is quite laborious, as the fruit bunches are harvested from the trees by hand using a sickle. The bunches are cut from trees, gathered and taken for processing. Normally, palm fruit processing occurs in close proximity to the plantations because, within hours, the triglyceride is broken down by lipase, which liberates free fatty acids and lowers the quality of the crude palm oil. Normal palm oil contains around 5 percent free fatty acids.

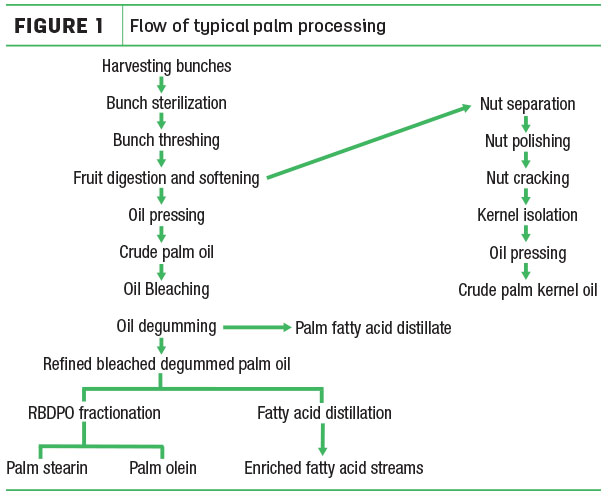

The first step in palm fruit processing is oil extraction, as shown in Figure 1. The bunches are sterilized, typically using steam to loosen up the fruit from the bunch as well as to denature lipase enzymes to stop the hydrolysis of triglycerides to free fatty acids.

Threshing then liberates the fruit before it goes into a digester to separate the mesocarp from the nut and allow for the mesocarp to be pressed, saving its oil. The separated nuts continue on to be polished and finally cracked to liberate their kernel oil.

Threshing then liberates the fruit before it goes into a digester to separate the mesocarp from the nut and allow for the mesocarp to be pressed, saving its oil. The separated nuts continue on to be polished and finally cracked to liberate their kernel oil.

The kernel stream goes to a different press than the mesocarp stream, hence generating two distinctly different oil streams with markedly different fatty acid profiles (Table 1).

Refining of crude palm oil

The purpose of refining is to remove the free fatty acids and any impurities such as gums, minerals, dirt, shell and oxidation derivatives. The refining process has a series of heating steps followed by filtration to separate all the different impurities. The new raw material is called palm fatty acid distillate (PFAD), a byproduct of the refining process.

At this point, the refining of crude palm oil is complete, leaving two products: refined bleached degummed palm oil (RBDPO) and PFAD. The PFAD is generally sold into the animal feed industry to make the typical calcium salt products fed to dairy cows, whereas the RBDPO can be sold to various industries or further processed by either fractionation or distillation.

Fatty acid fractionation and distillation

Fractionation is the most cost-effective way to separate the components of RBDPO into two main raw material streams. These streams are palm stearin (a more solid product) and palm olein, a more liquid product than RBDPO. Fractionation of RBDPO is a relatively simple process done in two main steps: crystallization and filtration.

Crystallization consists of a series of cooling and agitation steps in order to separate the glycerides based on their melting point. Separation yields RBD palm stearin and RBD palm olein. The palm olein is the premium product that brings a higher price and contains about 40 percent C18:1 oleic acid and 42 percent C16:0 palmitic acid, compared to stearin which contains around 54 percent C16:0 and 32 percent C18:1. The higher oleic-enriched olein is then typically sold into the edible oil market.

Palm stearin and olein are major commodities sold into various markets. However, highly enriched fatty acid streams are more valuable as single fatty acids, which are used in many different industries from cosmetics to animal and human food.

Enriched fatty acid streams are produced using distillation. Distillation is a process in which components are separated based on boiling point and molecular weight, where heavier fatty acids (such as C18:1) are separated from the lower weight (such a C14:0).

The number of distillation columns used and their size are based on how many fatty acids are in the oil and how highly enriched the fatty acid stream needs to be. The higher the purity of the fatty acid product, the more distillation columns needed and the more heat and time required to produce, resulting in higher production costs.

Products for dairy cattle

Palm-based fat supplements for dairy cattle are becoming increasingly more popular. As new research is being published, and we learn more about fatty acid nutrition, it is important to realize not all palm products are created the same. For example, a recent study published by Michigan State University researchers showed the importance of feeding specific combinations of fatty acids and not just simply feeding fat.

There are multiple raw material streams a product can be made from, each containing different fatty acid profiles and varying degrees of enrichment. Products made with PFAD have different fatty acid profiles than products made from distilled palmitic acid (83 percent C16:0).

Because PFAD is a byproduct of fatty acid breakdown post-harvest, its fatty acid profile can vary depending on the harvesting practices and times. If a product is made from tallow and is not palm-based, then its fatty acid profile will obviously be markedly different.

Take the time to ask your fat supplement provider for the fatty acid profile of the product you are buying and how the product is made. Make sure the product is formulated for the cows’ needs and not based on what raw material stream is the cheapest. ![]()

John Sylvester, Ph.D., P.A.S., is the director of new business for Perdue AgriBusiness Animal Nutrition. Email John Sylvester.

References from author available upon request. Click here to email an editor.