Over the past 50 years, a great deal of research has been done to improve our knowledge of grain storage, both the physical properties of grain and storage equipment. Technological solutions, which have exploded in number in recent years, provide producers more ways to achieve better storage, preserve grain quality and reduce drying and storage costs.

Mixed drying, a time-and money-saving solution

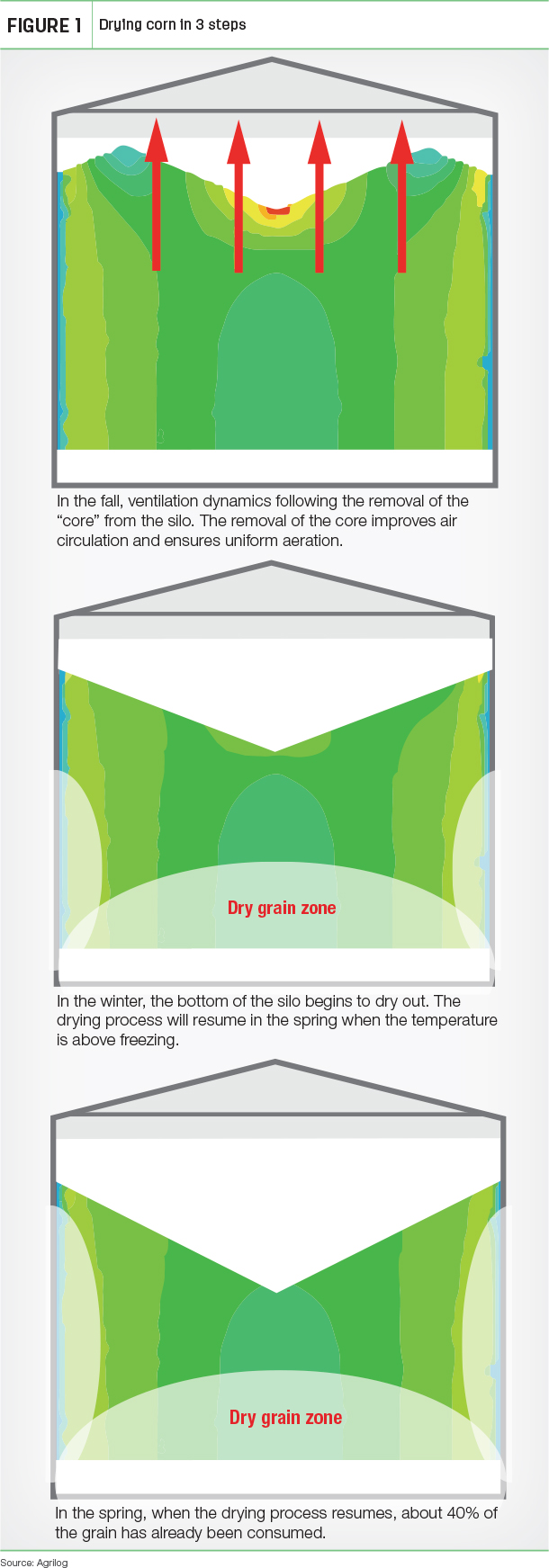

A good example of the solutions available to producers is the mixed drying (Figure 1) proposed by Serge Fortin of the CEROM grain research centre in Quebec.

In concrete terms, to use mixed drying, the producer must let the corn dry in the field, cool the grain as soon as it is harvested, consume the fresh grain until spring, then dry the remaining grain in the spring in dry weather. As a rule, if 100 tonnes of grain corn is stored and consumed per year, 40% of the grain will be consumed before the drying stage during springtime. For a corn grain at 25% moisture content, and a drying charge of $25 per tonne, this is a savings of $1,000.

In more northern regions like ours, where some operations produce and consume their own grain, it is possible to eliminate the corn drying stage, which results in significant time savings as well as a drying saving of $25 to $35 per tonne. This approach also improves the nutritional value and quality of the grain, in addition to guaranteeing maximum weight. Research has shown that corn dried in a mixed dryer was 2 to 4 kilograms heavier than corn dried in a continuous dryer.

Of course, there are grain handling changes to consider. The grain that will be stored must not exceed a moisture threshold of 25%, as beyond this threshold, grain ventilation is difficult and the risks of heating the grain, or of mold development, are high. It is also very important to have an adequate aeration system to quickly cool the grain in the fall and to have an adequate drying capacity in the spring.

Technological tools to help you

The most economical solution to monitor the condition of the grain is the hygrometer. It allows you to measure the outside temperature and moisture (like a weather station) and can also be used to assess the moisture at the outlet of the silo. Moisture above 65% is an indicator the grain is still wet. It is estimated to cost about $300.

An automatic control system allows for automatic start and stop of ventilation based on weather conditions on the farm. This control system can double the efficiency of the drying process and reduce silo interventions. The price for an automatic control system is between $1,650 and $2,150.

For the more technophiles who want information at their fingertips, putting the control system data in the cloud makes it possible to automate ventilation, to know the status of ventilation systems in real time and to control equipment remotely. This connected approach, via the internet, makes it possible to be alerted by text message or email when an anomaly occurs, 24 hours a day, seven days a week.

Finally, organic acids can be applied to the grain to control mold from the field and mold present in the silo. Organic acid-treated grain has been shown to maximize digestibility, palatability and help maintain intestinal flora of cattle, all at a low cost (about $5 per tonne).

Final recommendations

To ensure the success of storage, it is recommended to gradually integrate the mixed approach. This way, producers will become familiar with the method, gain experience and avoid compromising the quality of his grain. In addition, it is recommended to:

- Reduce rotor speed during harvesting

- Ensure a clean harvest free of debris

- Have a silo with good aeration (between 1.5 and 2 CFM per bushel)

- Do not exceed 18 feet of grain wall

- Equalize the grain level during the drying period

- Install ventilation guides on the inside wall of the silo.

Failure to follow the recommendations could result in serious consequences.

For batches of 100 to 200 tonnes, the mixed drying approach allows a cost reduction of $25 to $35 per tonne, improves quality and is suitable for producers/consumers. For those who are not familiar with the principles presented in this article, we strongly recommend you consult an expert to guide you in this approach.

References omitted but are available upon request. Click here to email an editor.

Steps to follow for mixed drying, by season

Successful mixed drying must include a thorough management of the at-risk zones in the silos.

In the fall

- Wait until the end of the hot season (early November).

- Apply organic acids to the grain before storage in the silo to help stop mold development.

- Consume or remove the heart of the silo quickly (about 3 to 5 tonne).

- Ventilate regularly to cool the grain mass (all November).

In the winter

- Ventilate the grain weekly to keep the grain mass cold.

Keeping the grain mass cold maintains the grain in a state of hibernation. However, it is advisable to avoid ventilating the grain in very cold weather. Ventilation is ideal when the temperature is between -3ºC and -8ºC.

In the spring:

The heat of the action

- Heat the grain mass and dry the grain with forced air.

o Temperature: between 10ºC and 20ºC

o Moisture: less than 70% moisture

- Avoid ventilating the grain when the outside temperature is above 20ºC.

- Have a ventilation of 1.5 to 2 CFM per bushel.