As an industry, we’ve made significant strides in improving feed efficiency. However, when we dig deeper, we have some work to do. Protein is one of the most expensive parts of the ration and there remain vast opportunities to improve protein efficiency.

Improving how we feed protein not only improves financial sustainability, but has benefits for the environment as well. Unfortunately, many people are still trapped in how they feed protein, formulating rations based on crude protein percentages – a method we now know is inefficient, both nutritionally and financially.

The problem with only looking at crude protein is twofold; first, the number really only represents the nitrogen quantity within the protein. It does not give any real measurement of the protein quality or amino acid profile. Amino acids are the actual nutrients that make up protein, upon which an animal depends.

Second, the animal needs amounts of these amino acids measured in grams, not percentages. If an animal has high dry matter intake, she will require less percentage to get the same amount as an animal that has low dry matter intake. Intake affects amount. While crude protein percentages served our industry well for many years, the science is very outdated.

Thanks to advancements in research and technology, we have a much deeper understanding of protein nutrition that allows us to move past crude protein percentages and formulate rations that balance for the true nutrient needs of the animal: amino acids, the building blocks of protein.

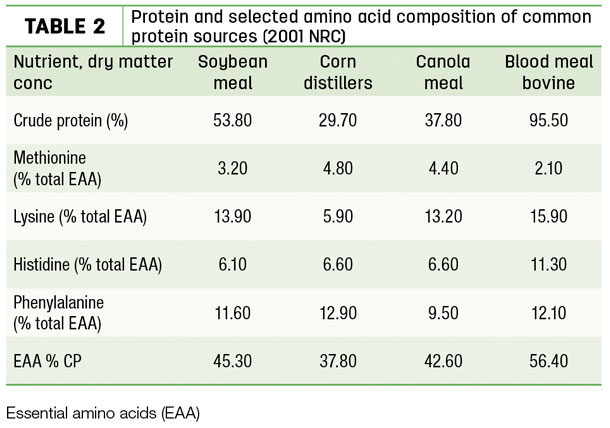

We also know not all protein sources provide the same amounts or digestibility of amino acids. For example, soybean meal is significantly higher in lysine than canola meal. More importantly, we know that some amino acids, like lysine, methionine and histidine, are limiting nutrients.

If the cow’s diet doesn’t provide a limiting nutrient in sufficient amounts and she is unable to synthesize it, it will limit her performance. By focusing on providing the right balance of amino acids, we can often provide the necessary amount of these key nutrients at a lower rate of total protein.

Amino acid balancing allows us to formulate rations with much greater precision, to match the specific needs of the animal as they evolve through each stage of life and feed protein much more efficiently.

While the idea of amino acid balancing has been around for decades, the practice is still not widespread or being utilized to its full benefit. Many people still focus on protein at the ingredient level and this can lead to instances of overfeeding.

Let me lay out a common scenario for you; a commodity broker calls up with a good buy on canola meal, which has a good cost per unit of protein. Since times are tight and you are looking for ways to save money, you take advantage of the price and stock up. However, when your nutritionist tries to balance the ration for amino acids, he finds your ration low on lysine.

Since lysine is a limiting nutrient, it’s crucial to meet this need, so the nutritionist has to add a greater amount of canola to meet the lysine requirement or performance will be limited. This leads to feeding more total grams of protein than is truly needed.

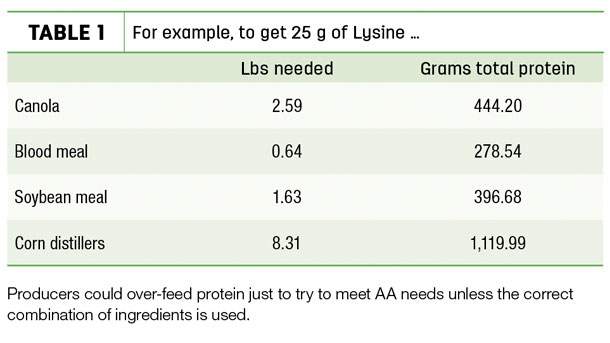

Had the protein source been something different that is higher in lysine, like soybean meal or blood meal, the total amount of protein fed could have been less (Table 1).

In this instance, purchasing the canola for your ration is like buying oil for your car when what it really needs is gas. So even though canola was a good buy, the amount that would have to be fed is higher than needed, possibly making the ration more expensive and also increasing nitrogen levels.

A high nitrogen level must be managed meticulously for impacts to the environment and the cow.

To excrete the extra nitrogen from her body, the cow will require lots of water intake and some energy; energy that she won’t be able to use toward other functions, such as milk production. The excessive nitrogen can also seep into the blood, resulting in high blood urea nitrogen (BUN) and consequently the milk, identified as milk urea nitrogen (MUN).

If you’ve ever had a MUN over 16 on your processor report, then you are getting very poor protein efficiency and need to analyze your ration.

High urea nitrogen levels can negatively impact an animal’s ability to properly conceive and carry a calf to full term, which can lead to costly early embryonic deaths and other reproduction-related expenses.

After wreaking havoc on the cow’s system, the excess nitrogen eventually lands in the environment, where it continues to be a problem. Ultimately, all of this can be prevented if we improve how we manage the protein going into the cow.

What’s holding many people back from improving how they feed protein is really a paradigm shift, not a lack of tools. We have a plethora of technology available to us today, from ration formulation software that is constantly being updated with nutrient data to near-infrared devices that rapidly measure nutrients that help make it possible to balance rations for amino acids.

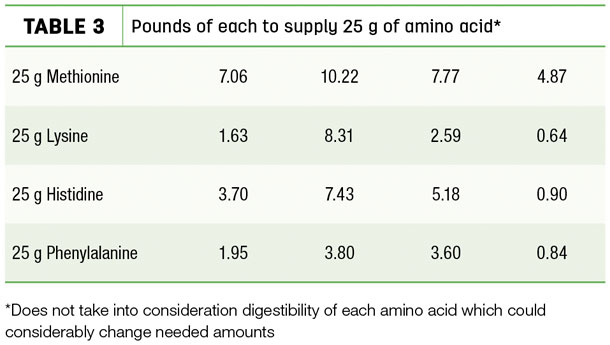

For some nutritionists and producers, embracing these technologies and improving protein efficiency will require a shift in the way they view protein and make purchasing decisions. They will need to stop thinking about protein ingredients like soy and canola, and start thinking about the key nutrients those ingredients supply (Table 2 and Table 3).

The cow doesn’t really need protein, she needs the amino acid nutrients in the protein. Work closely with your nutritionist to understand the nutrient base of your homegrown forages and identify the gaps.

Then focus on formulating a ration and purchasing feedstuffs that fill those nutritional gaps.

As our industry becomes more enlightened in this area, significant advances will be made. Sharpening our precision on how we feed protein by balancing for amino acids will help producers realize greater returns on their feed investment, while helping them be better stewards of their environments. ![]()

Floyd Hoisington is a dairy specialist with Cargill. Email Floyd Hoisington.