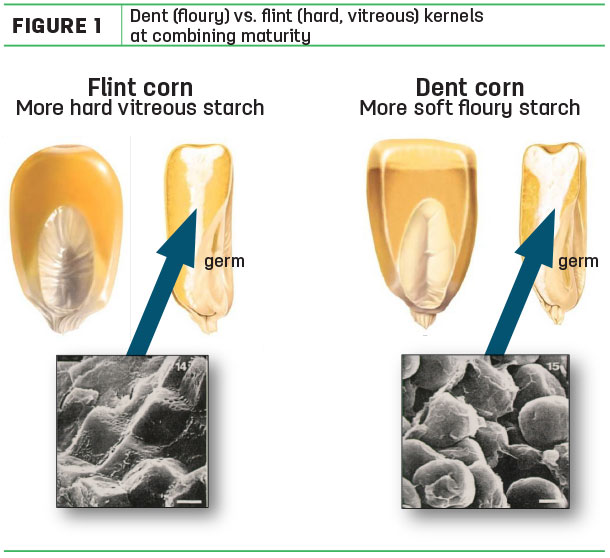

What these discussions are referring to is the amount of floury (also called soft or dent) starch versus vitreous (also called hard or flinty) starch.

While flint hybrids are still commonly planted in the maritime environments of Northern Europe, very little flint background exists in high-yielding hybrids planted in North America.

Dent corn derives its name from the fact that the softer starch “dents” in at the top of the kernel as it dries down. An example of flint corn would be popcorn with very hard kernels containing mostly hard, vitreous starch.

When considering starch digestibility, it is important to identify if one is talking about kernels in fermented corn silage, which are harvested at one-half to three-quarter milk line, versus kernels that have been combined after reaching black layer maturity.

Differences in kernel test weight at combining clearly demonstrate that there are differences in the amount of hard starch between hybrids. Research from France shows that grinding dry corn to less than 1,300 microns essentially removed any negative effect of even very hard, high test-weight kernels.

In North America, most nutritionists understand this fact, explaining why dry corn in most dairy diets is ground to less than 800 microns.

Research among hybrids grown in the same environment (plot) has not shown significant differences in the amount of hard starch in the more immature (pre-black layer) kernels harvested at corn silage maturities.

Research has also shown very minor differences in pre-black layer kernels between hybrids when analyzed in commercial laboratories for seven-hour ruminal starch digestibility.

It is also clear that after two to three months of ensiling, the fermentation acidification process further reduces any minor differences that may exist in starch digestibility between hybrids due to being grown in different fields with varying growing environments.

The other consideration is if one is talking about ruminal starch digestion, intestinal starch digestion or the sum of the two, often called “total tract” starch digestion.

Dairies can easily test for fecal starch levels, and if under the goal of less than 3 percent starch, it can be assumed that the dietary starch was digested in either the rumen or intestines.

Most high-producing dairies that have tested starch in the manure show less than 3 percent starch, which further puts into question the claim of significant differences in starch digestibility.

The amount of starch digested in the rumen is important because it drives rumen microbial populations, which are an ideal source of protein as they are digested in the intestines.

However, too much ruminal starch digestion can lower rumen pH, which can reduce fibre digestion and negatively impact milk components. Starch digested in the intestines provides more energy for the cow because there are no gaseous losses that occur when starch is digested in the rumen.

However, dry corn and silage kernels need to be processed adequately to ensure that starch granules escaping the rumen have adequate surface area so they can be digested by intestinal enzymes.

University of Wisconsin researchers have developed a starch digestibility index called UW Grain Evaluation 2.0. Their extensive research into starch digestion shows that if the kernel was fermented (e.g., corn silage, high-moisture corn), the factors that influenced starch digestion were particle size and the amount of time in fermented storage.

The type of starch (soft or hard) was not a factor they considered important in corn silage or high-moisture corn. When kernels were to be fed as mature, dry corn, the two factors they considered important were particle size and amount of hard starch.

This makes sense given test weight differences (more hard starch) at combining maturity and reinforces research at Ohio State University and France that shows fine grinding dry corn offsets the negative impact of more hard starch in mature kernels. How fine to grind can be fine-tuned by monitoring fecal starch levels.

The best way to optimize starch yield and digestion in a silage hybrid is to focus on agronomics, yield potential and ensure a good job of kernel processing.

If inventory allows, do not feed until the silage has fermented for two to three months so that the new-crop corn silage has a ruminal starch digestibility similar to the old crop that has been in the silo for the past year.

For dry corn, focus similarly on agronomics, yield potential and fine grind to less than 800 microns. ![]()

-

Martina Pfister

- Dairy Specialist – Central/Eastern Ontario & Maritimes

- Dupont Pioneer – Canada

- Email Martina Pfister