Optimal forage management, from harvest to feeding, is essential to improve milk production, minimize health problems and increase farm profitability.

Forages are the basis of dairy herd feeding programs, and their optimal use has a significant impact on farm profitability. They provide cows with the nutrients they need to support their maintenance, growth, production, health and reproduction.

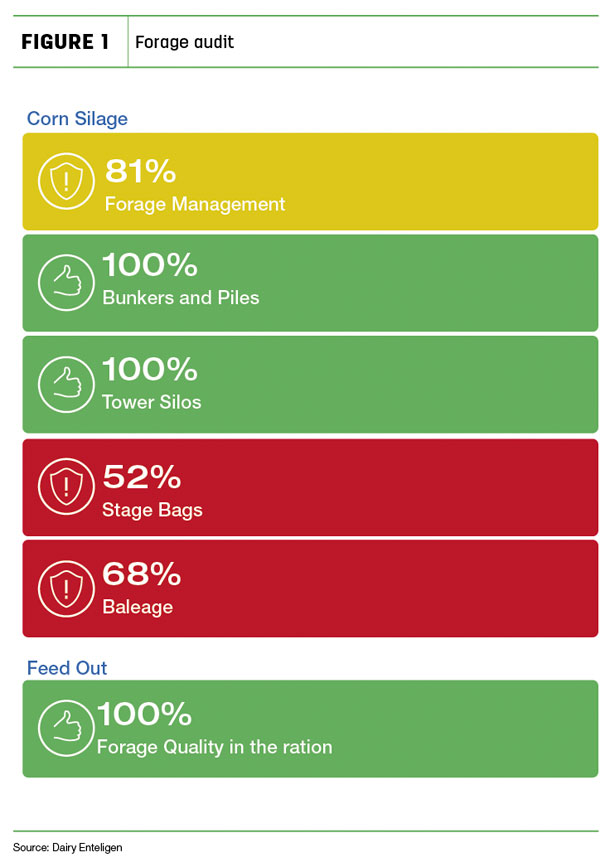

A mild variation in their quality will impact ruminal stability and thus milk production. Therefore, the use of key indicators during harvest, storage and feeding allows producers to target profitable opportunities (Figure 1).

There are different tools available to assess the quality of a forage in relation to its fermentation profile. Depending on the laboratory, it is sometimes possible to compare silage analysis with the average of similar samples or forages from previous years.

Harvest period

Harvest management greatly influences the quality of forages that will be fed during the following year. The quality of the forages is negatively correlated with the maturity of plants at harvest, which directly influences acid detergent fibre (ADF) and neutral detergent fibre (NDF) levels. Greater maturity increases the thickness of the plant wall (level of NDF), which leaves less space for other nutrients, resulting in a loss of overall nutritional value (energy, proteins and digestible fibres).

The increase in NDF also increases the value of uNDF240, a measure of undigestible fibre, and limits intake due to faster ruminal filling. Thus, better-quality forages will limit the use of concentrates in the ration and stimulate the consumption of cows, which in turn will stimulate milk production.

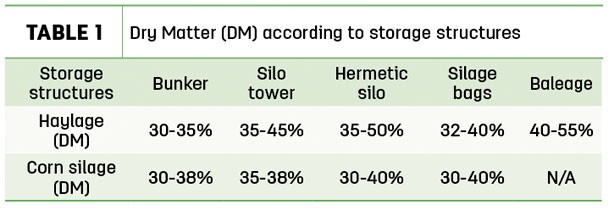

Dry matter (DM) at harvest is one of the most important criteria, since it will dictate the conservation of the forage. It is important to note that the ideal rate of DM is specific to each storage structure (Table 1).

When DM is too low, it increases chances of nutrients leaching out of the silo. In addition, water (neutral pH) buffers the silage, leading to a higher pH level and incomplete fermentation. This directly impacts the quality of the silage, since incomplete fermentation allows bacteria to consume the plants’ nutrients over a longer period of time.

With higher DM, water available for fermentation by bacteria is limited and silage compaction is reduced, allowing for air pockets, making the silage unstable at feeding.

A key indicator to decide on the ideal timing to take the first cut is the 15-24-30-inch rule, which is based on the height of the alfalfa to determine the maturity of the haylage. The ideal harvest maturity in a mainly grass field is when the alfalfa reaches 15 inches tall. For a 50-50 mix, the target height is 24 inches and, in a pure alfalfa field, the target height is 30 inches. For subsequent cuts, standard intervals of 28 to 32 days are required.

Mowing early in the morning allows for faster drying, which retains more of the plant nutrients, especially sugar. Sugar is a key precursor to fermentation. Mowing later in the day increases the amount of sugar in the plant, but this sugar will be consumed through cellular respiration until the plant’s humidity reaches 50%, resulting in a greater loss of nutritional value.

The length of chop affects ruminal health by stimulating rumination. Consequently, it is necessary to control it by validating the knives’ efficiency before each use to have a clean and uniform cut of forage. Theoretical lengths of cut between 3/8-inch and 1/2-inch for haylage and 3/4-inch to 1 inch for corn silage, according to the storage structure, are aimed. The use of a kernel processor greatly increases the digestibility of the starch.

In all cases, contamination of forages with soil particles should be avoided. This can occur by mowing too close to the ground, picking up soil, spreading manure before cutting or having dusty roads near the field. This will affect the level of ash, the pH, as well as the level of volatile fatty acids, which will negatively affect fermentation.

Ash level targets should be lower than 10% for haylage and lower than 5% for corn silage. Ash contamination is reflected in the fermentation profile when corn silage has exceptional lactic acid levels (greater than 7%) or high butyric acid levels in the case of haylage.

The use of inoculant can also be considered at harvest to reduce the loss of DM and sugars. The selection of an inoculant should be based on the DM of the silage. Also, it is important to calibrate the applicator for each use to avoid underdosing or overdosing.

The use of an inoculant containing strains of lactic acid bacteria will promote the production of acid. Inoculants quickly lower the pH, allowing appropriate fermentation to be reached faster.

Fermentation creates heat and releases CO2, which burns the sugars in the plant, thereby reducing the nutrients available for the rumen. Buchneri-based inoculants use lactic acid to produce acetic acid, which improves silage conservation. This acid is most valued at feedout, as it limits the growth of yeasts and moulds, increasing the stability of the silage. Adding buffered propionic acid can also improve the conservation of silage by controlling mould.

Storage period

The two main objectives of a good fermentation are to maintain nutritional quality and minimize DM losses. To do this, it is essential for the silage to be placed in an oxygen-free environment within 12 hours of harvest and until feeding.

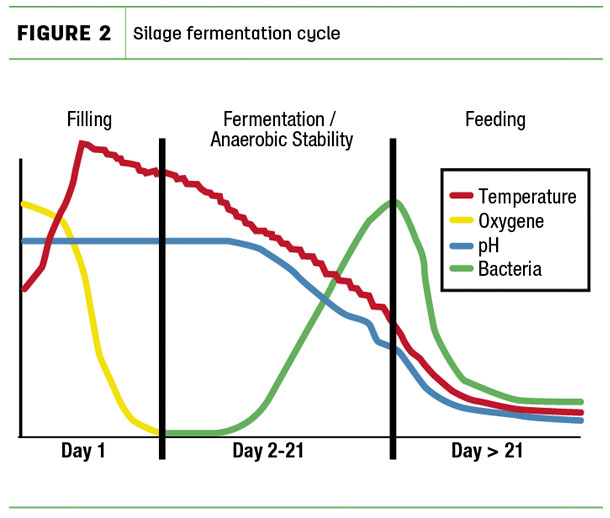

The fermentation cycle is divided into four phases (Figure 2).

The aerobic phase (filling) includes respiration (conversion of sugars to CO2 and water) as well as proteolysis (conversion of proteins to amino acids). To limit the loss of nutrients, it is important for this phase to be as short as possible, aiming for rapid drying times in the field and air-tight storage structures.

The fermentation phase is characterized by the dominance of lactic acid bacteria, which proliferate only under anaerobic conditions. The growth of these bacteria causes a rapid drop in pH by lactic acid.

A pH below 5.0 limits the presence of organisms harmful to silage. Once the pH of the silage is lowered and maintained, very little microbial activity is observed (anaerobic stability phase).

Maintaining a low pH prevents the development of butyric bacteria from soil contamination. These reduce the energy and the DM of the silage (storage losses) in addition to emitting a strong odour which limits consumption and thus performance.

The fourth phase begins at feedout when the storage structure is opened. The reintroduction of oxygen allows the proliferation of aerobic microorganisms. This phase is inevitable, but some practices can be implemented to limit its impact on the quality of the silage, in particular, heating.

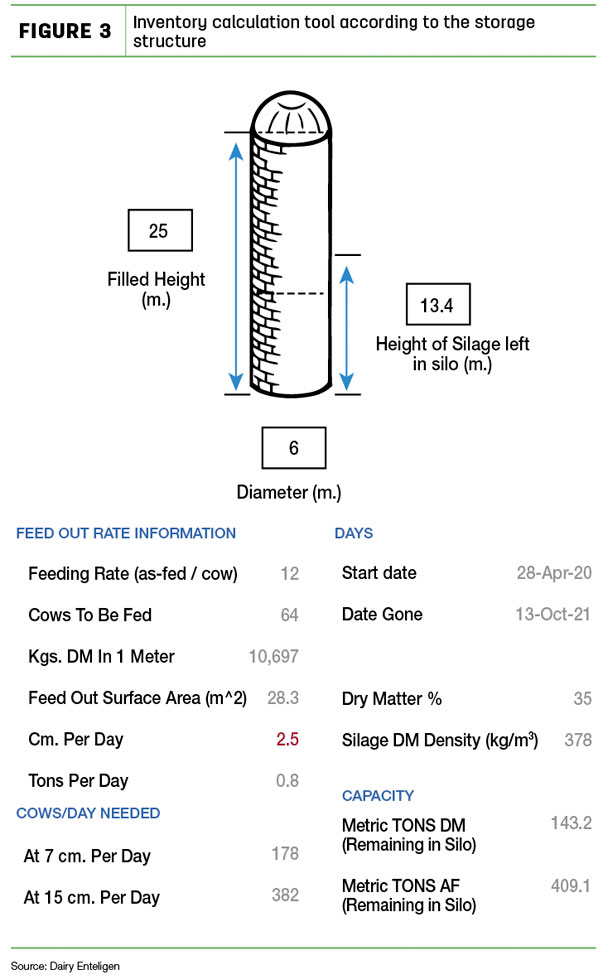

First, the calculation of inventories (dimensions of storage structures versus livestock) validates the feeding rate is appropriate for the size of herd (Figure 3).

Proper compaction of the silage will also restrict oxygen contact with the forages. Finally, a judicious choice of inoculant will limit the activity of microorganisms during feeding.

Proper compaction of the silage will also restrict oxygen contact with the forages. Finally, a judicious choice of inoculant will limit the activity of microorganisms during feeding.

Feeding phase

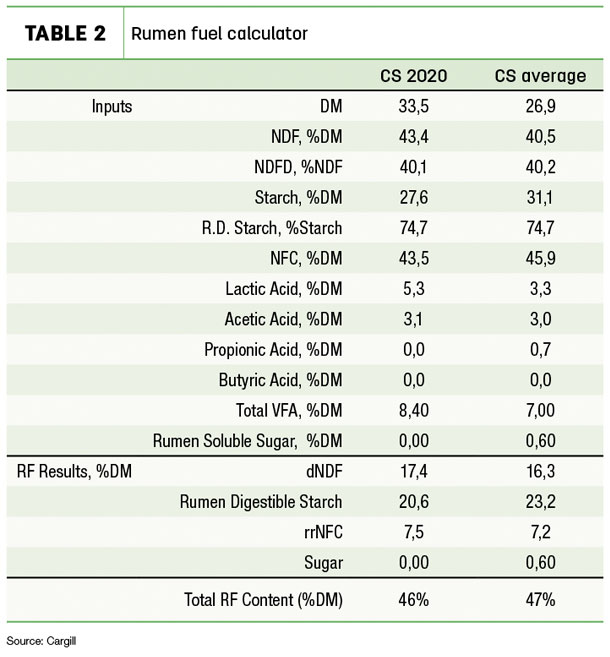

In order to ensure optimal nutrition, it is essential to take a representative analysis of the silages to assess their quality. Some software programs provide a theoretical value for quality compared to the regional average. Often expressed in terms of nutrients and fermentation, this calculator determines the rumen fuel (Table 2).

Take the time to assess the levels of digestible fibre and starch and the quality of the fermentation to optimize the use of ingredients on the farm, the ration and the profitability.

The frequent analysis of the DM (Koster) of the silages also allows dairy producers to be proactive when faced with variations in consumption. The length of chop out of the mixer is as important as that at harvest.

Make sure the mixer knives are well sharpened and the mixing time is adapted to ensure a clean cut of the forages, which will stimulate rumination. The fibre efficiency of the ration is validated using the Penn State particle separator. An audit of the mixture can be done to validate the consistency of the ration served.

A comparison of fresh ration and refusal is a good indicator of the level of sorting. Minimizing sorting allows a stable ruminal pH and a better overall cow health. Also, feeding forages containing high levels of mycotoxins can limit consumption, performance and reproduction, depending on the type of mycotoxins.

To reduce the impact of this feed, it is possible to dilute its proportion in the ration or to add a specific anti-toxin. A clean harvest and proper storage will help limit the growth of moulds that cause mycotoxins.

Conclusion

There is a great deal of information in the literature on the optimal management of harvesting sites. Even though there are many good practices that can be used on farms, it is important to keep in mind that setting objectives and respecting key indicators are essential to obtain good results when feeding forages. Good harvest, storage and feeding management will allow for high-quality forages that will provide great nutritional value, promote consumption and production, which will improve profitability on the farm.

References available upon request. Click here to email an editor.