Winter brings cold, harsh weather with low humidity – the perfect conditions for teat-skin chapping, damage and hyperkeratosis, the most common teat-skin and teat-end problems. Even when temperatures are in the 30s, combined with wind speed around 20 to 25 mph, frozen teats are likely to occur if preventative measures aren’t in place. During these cold months, teat-skin damage is a major factor predisposing cows to mastitis.

By addressing winter conditions before they arrive, dairy producers can minimize teat-skin damage and the resulting loss of profitability from elevated SCC and clinical mastitis. Utilize the strategies below to keep your herd healthy and producing high-quality milk through winter by establishing a winter teat-care program and preventing teat damage before it occurs.

1. Preconditioning

Healthy teat skin is crucial to help the cow fend off intramammary infections. By addressing winter weather and teat-skin condition before the temperatures drop, producers can minimize damage and the resulting loss of profitability from elevated levels of somatic cells.

Teat-skin thickness changes rapidly during extreme changes in temperature, so it’s important to condition the teat skin to keep it flexible before colder weather hits.

Increasing the amount of emollients in your post-dip well before winter will help precondition the teat skin, making it more flexible and ready for the change in weather.

Chlorine-dioxide teat dips which contain lactic acid have been very successful at exfoliating teat skin to slough off excess keratin, helping to reduce hyperkeratosis, making teat ends smoother. Smoother teat ends harbor less bacteria and are easier to clean.

Start early in preconditioning teats to prepare the teat for winter weather well before it hits. This will eliminate the impossible task of predicting weather.

2. Winter teat-dip plan

Post-dipping is just as important in the winter as it is in the summer to control mastitis.

Selecting a proper teat dip that is formulated for your cows’ winter weather environment is crucial. Emollients are a critical element in winter teat dips as they protect, heal and soften skin in harsh weather. As soon as the weather starts to get cold, use a post-teat dip that contains a higher level of emollients balanced with the proper protection against mastitis.

When the cows’ environment hits below freezing, use a winter teat dip with high levels of emollients (preferably between 74 and 76 percent) with an extremely low freezing point (-76ºF on average) to protect your cows.

Have a plan for when you will switch between your base-high emollient teat dip and when you will switch to your winter teat dip (low freeze point), and make sure it gets implemented correctly and keep it simple. Conventional water-based dips freeze solid around 29 to 32ºF. A good winter teat dip should also include an effective germicide proven to kill mastitis-causing bacteria.

3. Maintain equipment and optimize automation

Just as it is important year-round, it is even more important to start off the winter season knowing equipment is functioning properly.

It is best to make sure scheduled service is on schedule before going into the winter months. Performing both static and dynamic (while milking) tests as well as making sure parts are replaced at the recommend interval are key.

Make sure your current equipment settings are optimal to your cows’ current milk production and the liner you are using. Settings that are too low or too high than the optimum for vacuum and pulsation will increase teat stress and aggravate teat-end condition.

Detacher settings with a milk flow rate that is too low prolongs unit on-time and causes excessive compression against the teat end (due to vacuum level increases during low flow periods).

Evaluate and optimize system settings prior to winter weather’s arrival.

4. Precise milking procedures

Proper milking procedures are crucial to harvest high-quality milk safely and quickly. Your milking procedure should allow for proper stimulation, milk let-down time (90 to 120 seconds), clean teats, proper unit attachment and alignment.

Milkers should be educated on the challenges of winter weather and the effects on teat tissue. Because of the rough, flower-like characteristics of hyperkeratosis, soil can be trapped on teat ends, making cleaning much more difficult.

Operators need to wipe teats in a downward, twisting motion, flip the towel to a clean area and make a second more aggressive wiping pass across teat ends, applying pressure with the towel to ensure the teat ends are clean before attaching the unit. This will improve teat cleanliness and help to remove excess keratin buildup that is ready to come off the teat.

Make sure to have a “rub, no pick” policy in cleaning teat ends. Picking at hyperkeratosis (rough teat ends) that is not ready to be removed can cause pain and bleeding and puts the teat at further risk of infection.

This is an essential step to help keep teat skin healthy and to prevent hyperkeratosis-related mastitis infections from invading the herd and harming milk quality.

5. Prime housing environment

Managing the environment will minimize the impact of winter weather on teat-end health and is especially important for fresh cows. Fresh animals are more prone to teat damage as they have less circulation in their udders and more swelling.

Bedding is a key component to preventing environmental mastitis, but it’s especially important in winter to keep bedding dry to prevent ill teat-skin effects and prevent it from freezing in the stall. This might mean more frequent bedding and using less recycled bedding in the winter. Be sure to monitor stall usage; a decline may indicate frozen bedding or clumps of frozen bedding in the stall.

Wind blocks can help reduce wind speeds and prevent chapping or frostbite. Cow housing that keeps cows free from wind and cold can have significantly better teat conditioning. Also, be sure alleys and holding pens are kept especially clean with frequent scraping, especially before a super-cold spell is predicted to hit.

Careful attention to these five elements can limit the impacts of cold weather and help keep teats healthy all winter long. Healthy teats mean high-quality milk and healthier cows, and that’s more profit in your pocket. PD

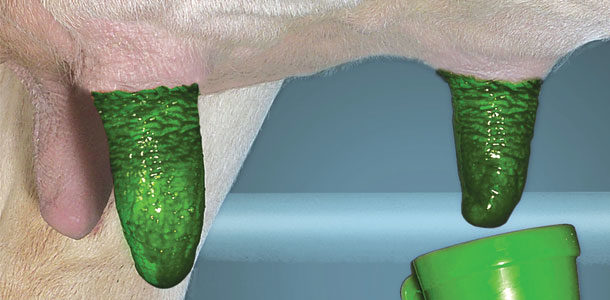

PHOTO

Start early in preconditioning teats to prepare the teat for winter weather well before it hits. This will eliminate the impossible task of predicting weather. Photo courtesy of GEA Farm Technologies.

Keith Engel

Dairy Farm Hygiene and Supplies Specialist

GEA Farm Technologies