A May 8 webinar offered dairy producers advice and reminders about preventing lameness. The hour-and-a-half presentation featured Penn State Extension Veterinarian Ernest Hovingh and Extension Dairy Team member Dan McFarland, an engineer, and explored the relationship between flooring, footing and lameness. “It’s not quite as simple as saying there’s one individual thing that determines whether or not a cow becomes lame,” Hovingh says. “It’s almost always an interaction between a number of different factors.”

He advises producers to look at lameness like they would at building a house. Take into account the many aspects of design and engineering: think about the materials used (both quality and quantity) as well as the quality of workers, in order to build as durable and functional house as possible.

However, he pointed out that it’s also important to plan for and reduce the negative effects of the environment of the house: soil conditions, weather (rain, snow, wind) and pests.

The same ideas can be applied to hoof health, he says.

“It’s critical to ensure that your cows not only ‘build’ very healthy feet from the inside out, but that the environment they’re in is as favorable as possible for them,” Hovingh says. And since most lameness injuries occur in the feet, it’s important to look at preventing lame cows literally from the ground up.

“It’s critical to ensure that your cows not only ‘build’ very healthy feet from the inside out, but that the environment they’re in is as favorable as possible for them,” Hovingh says. And since most lameness injuries occur in the feet, it’s important to look at preventing lame cows literally from the ground up.

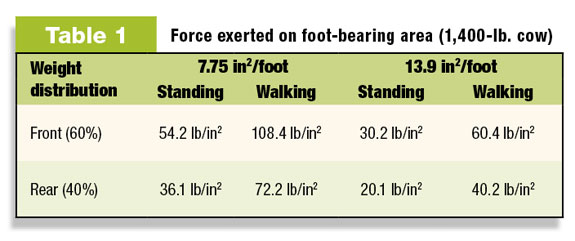

“It’s a fine line between rough and smooth,” McFarland says. “Hard, unyielding floor surfaces create pressure points on weight-bearing areas, but surfaces too soft or smooth may cause slips, leading to injuries.”

( See Table 1 , above right, which references how a cow’s weight is distributed during standing versus walking.)

Concrete is a suitable and popular choice for many operations, but it’s important to get the details right, McFarland says.

“Look for an experienced installer with ‘cow sense,’” he says. He advises producers to look at other dairy farm work the installer has completed.

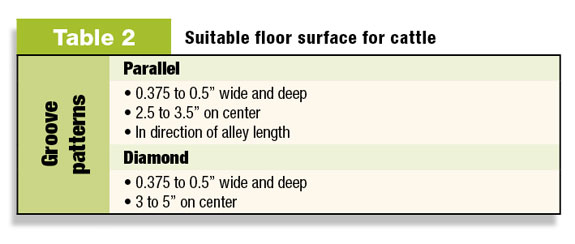

Effective concrete flooring should have a grooved pattern, with either a parallel or diamond-shaped grove pattern, and have proper depth, width and spacing. ( See Table 2. )

Both speakers referenced Penn State’s “Freestall Crossover and Floor Surface Details” publication, which provides additional guidelines to consider when pouring concrete for cattle facilities.

After pouring concrete, the presenters recommended producers closely inspect flooring for rough surfaces and sharp edges. Newly poured concrete should be sealed to minimize moisture penetration and reduce alkalinity, which can burn hooves, McFarland says.

He also says resilient flooring materials, such as rubber mats, are best used in areas where cows could use additional cushioning: treatment and hospital pens, holding pens around the parlor and in cow traffic lanes.

Once flooring is established, it’s extremely important to keep it maintained, McFarland says.

He advises producers to watch for and avoid:

• Uneven floor surfaces

• Debris on floor surfaces, such as stones or nails

• Wet, manure-covered cow alleys (research has shown that moisture from manure softens and weakens the claw)

Can anything be done to improve existing floor surfaces? Yes, but McFarland advises producers to do their homework.

Milling and scarifying concrete can take the polish and sheen off surfaces and provide better traction. Acid etching is also effective but proper protection is needed. Scabbling concrete even a shallow amount (1/8 of an inch) can improve traction.

Both Hovingh and McFarland advised producers to observe cows in action on floor surfaces. Excessive standing is abnormal behavior, McFarland says. Perching in stalls or idle standing in cow alleys may be an indication that something is off with the stall area.

Cows should be moved from one area to another of an operation with cows’ safety, not speed, in mind. If this is not being done, workers should be trained on how to move animals properly, Hovingh says.

Providing suitable flooring can be one of the most important ways to prevent lameness problems, but when issues are identified, producers should take action as soon as possible.

Hovingh also stressed that from an animal well-being and profitability perspective, clinically lame cows (with locomotion scores of 4 or 5) should be treated immediately by a properly trained individual. Cows with locomotion scores of 2 and 3 can receive attention through regularly scheduled hoof trimming. PD

To see additional details from the presentation, including recommendations for bedding and hoof trimming, and view the entire webinar, click here . Find recordings of other past webinars and watch for upcoming sessions of the Technology Tuesday Webinar Series from the Penn State Dairy Extension Team .

Emily Caldwell

Editor

Progressive Dairyman