Human nature requires that before we can correct a problem, we must first admit to a problem. This author believes there are three important reasons to define environmental mastitis as a problem. REASON #1: The 400,000 SCC limit for salable milk is coming to America As I wrote in a Progressive Dairyman article last fall, reducing this country’s SCC limit is long overdue. Now is the time to evaluate your dairy’s SCC history and decide if you are ready for the new regulations.

Some regions in the U.S. have SCC issues due to weather challenges, while farms across the country are experiencing elevated SCCs after switching to “alternative bedding” materials. The bottom line is that environmental mastitis is the primary driver for elevated SCCs on dairy farms today.

REASON # 2: FDA’s attention to milk and meat residues is increasing

All of us involved in the production of food from milk and meat are accountable for residues and the concerns raised by consumers regarding the safety and wholesomeness of our products. I will be the first to accept responsibility, as a dairy veterinarian, for casual supervision of written protocols and vague scripting language in the past.

I am currently in the process of reviewing every protocol and every drug label for accuracy with all my clients. But I will challenge you dairy producers to accept the new reality of strict attention to residue avoidance, especially in meat from cull dairy cows, and immediately begin to work more closely with your attending veterinarian. This includes updating all treatment protocols and making all label language align perfectly with all protocols.

Additionally, I strongly urge you to stop buying meds from drive-by scripters who do not have a valid veterinary-client-patient relationship (VCPR) with your herd. Work with your attending veterinarian. He or she will be the key professional by your side in the event of a residue issue.

And, of course, you all have a detailed inventory control system for your medicines … right? It’s the law and it will be one of the first questions you are asked when the FDA comes calling to investigate a residue complaint.

P.S. – Penicillin, used at the dosage rate we typically recommend, is extra-label (ELU) and requires a label on each bottle. You’re welcome.

REASON #3: Mastitis is expensive and corn is $7

The financial loss from mastitis has been well documented, but for most of you the loss is invisible … like termites eating your house. A lot of damage is being done to your financial house, with the only apparent expense coming from purchased mastitis tubes.

Dr. Schukken at Cornell, Dr. Fetrow at Minnesota and Dr. Ruegg at Wisconsin have analyzed the economics of mastitis and have put the average cost of a single case of mastitis from $179 up to more than $400. The largest part of this loss is from the milk dumped or the death of the cow.

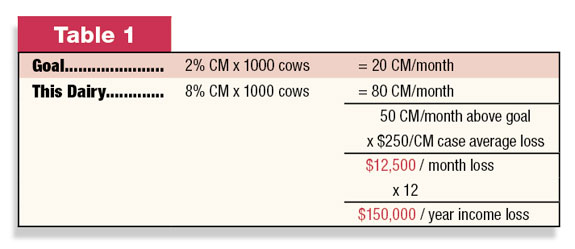

Are you tracking your incidence of clinical mastitis (CM) cases per month? The goal is <2 percent, which equates to fewer than two cases per 100 milking cows.

With the continued change in the U.S. dairy industry to lay cows on alternative bedding materials, many farms are not reaching the <2 percent CM per month goal, even with SCC levels in the 200,000 range or lower. So you must monitor both the SCC and the CM rate to evaluate your total milk quality status.

Let’s do a quick math story problem. Two trains leave a station at the same time in opposite directions … Oops, wrong problem.

A 1,000-cow freestall dairy is bedding with dried manure solids (DMS) from fresh scraped manure and has a BTSCC of 180,000 and a CM per month of 8 percent. The good SCC count is a credit to the milkers doing an excellent job of identifying new mastitis cases.

How much money is the dairy losing per month/year with this rate of CM? (See Table 1 .) This is not a hypothetical example. This author is seeing CM rates like this on some farms with alternative beddings.

Reducing environmental mastitis cases involves three steps.

Step 1

Establish a goal for CM in your herd and decide you really want to achieve that goal. Less than 2 percent CM per month is desirable and achievable. Calculate your own CM rate and how much money you are losing.

Step 2

Keep your cows clean and dry. Groom the beds or open lots daily. Use adequate straw in open lots during extreme weather. Make adjustments necessary to get cows to lie correctly in the freestalls to keep the beds clean.

Dr. Andy Johnson has developed a simple scoring system to evaluate cow positioning in freestalls he calls the “butt score.” 90 percent of cows lying in your stalls must have their “bums” positioned at the back edge of the curb so manure or urine will fall in the scrape alley. Dirty beds increase environmental mastitis.

Compounding the challenge of dirty beds is the increasing usage of alternative bedding materials like recycled sand and DMS (bio-solids). These materials increase the risk of environmental mastitis on their own. Switching to any of them requires strict attention to bedding management details. There is no room for error. Critical details include:

1. Butt scores must be 90 percent in all pens, including heifers.

2. You cannot switch to Jersey or crossbred cattle and expect them to lie correctly in stalls sized for Holsteins without adjustments.

3. Rinse water quality is critical in making “clean” recycled sand.

4. Dryness is better than yield when producing DMS.

5. Re-piling is critical to drain off water in DMS and recycled sand.

6. Increased air flow is critical in all barn types using alternative bedding.

7. Turn on fans when bedding in tunnel or cross barns, even in winter.

8. Raw manure DMS is more dangerous than digester DMS.

9. Cross-vented barns = high winter humidity = increased coliform mastitis.

10. To date no one can make good recycled sand in the winter – Stockpile!

11. Lime can help but too much can dry teat skin.

Step 3

Your last opportunity to reduce the risk of environmental mastitis is during the milking prep procedure. The two critical points are the towel activity and the pre-dip germicide’s killing ability.

Research has determined that a “perfect” prep procedure can reduce teat bacterial counts by 85 percent. This author’s observations suggest that most milking prep procedures fall well short of the 85 percent opportunity. Dirty teat ends are the primary deficiency.

When you start with bacteria-rich alternative bedding putting huge bug populations on teats and you add fast-paced parlor activity to maximize throughput, you end up with elevated rates of environmental mastitis.

Paul Peetz, technical service manager for Milk Equipment Dealers Association (MEDA) in Wisconsin, recently described the importance of the prep procedure this way: “You only have two or three times each day (based on milking frequency) to reset the bacterial population on your cows’ teat ends to a lower level. You have to make the most of each 15-second pre-dipping and towel wiping event.”

And just like managing the beds, there is no room for error in prepping cows when you are using alternative bedding. Critical details include:

1. Predip contact time – 45 seconds for iodine; 15 seconds for chlorine dioxide.

2. Chlorine dioxide kills the most bacteria in the face of organic load.

3. Bleach, hydrogen peroxide, chlorhexidine and other germicides struggle to kill bacteria in the presence of heavy organic load.

4. Brushes on pre-dip cups can become bacterially contaminated.

5. Teat skin must be kept smooth all year-round; higher emollients may be required during cold, wet or dry-windy weather.

6. Horizontal skin cracks can occur at the first cold snap with wet bedding.

7. No frozen teat ends can be tolerated; use winter dips; control wind.

8. Hyperkeratosis must be managed year-round; 80 percent smooth is the goal.

9. Dips with lactic acid to exfoliate rough teat ends may be necessary.

10. Cloth towels are better than paper; they clean more aggressively.

11. Cloth towels must be washed correctly; culture them to verify.

12. Wiping teat ends clean is mandatory, not optional! PD

References omitted due to space but are available upon request to editor@progressivedairy.com .

PHOTO

The “butt score”: 90 percent of cows lying in the stalls must have their “bums” positioned at the back edge of the curb so manure or urine will fall in the scrape alley. Photos courtesy of Roger Thomson.

Roger S. Thomson

Owner

Team Management Concepts

teammann22@aol.com