In comparison with other agriculture markets in Canada, the dairy goat market is still in development, which means producers face unique opportunities as well as challenges.

The industry is not supported by supply management and is more similar to the American dairy industry. This leads to price variability, which means it is very important for producers to know the status of their operation in order to get through difficult times.

Due to the stage of development of the industry, there is a lot of farm-to-farm variability in genetics, standard operating procedures, record-keeping and available infrastructure. This makes working at the individual farm level even more important to determine specific opportunities and identify bottlenecks.

Effective on-farm records are key to improving farm profitability. Utilizing on-farm data allows producers to get a good idea of how their operation is functioning and to set achievable goals for the future. B-W Feed and Seed has partnered with Archer Daniels Midland to bring a tool to dairy goat producers that helps with tracking farm data as well as providing benchmarks to other producers.

This tool enables us to move beyond nutrition to help determine where farms have the most potential to improve profit and maximize their margin. Working through the program with a variety of different producers has presented some interesting information regarding important metrics to track at the individual farm level to identify opportunities.

Return-over-feed is important to track to determine production efficiency as well as to help make investment decisions. This is a calculation based on the amount of revenue that remains after accounting for feed costs. It can be illustrative of the fact reduced feed cost doesn’t necessarily produce the highest return on-farm, especially if it results in sacrificing production.

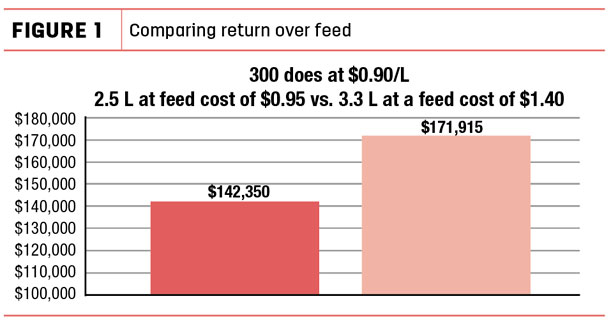

For example, in Figure 1, we will use an average milk price of 90 cents per litre and compare two farms with different levels of production and different daily feed costs.

If one farm is averaging 3.3 litres per doe and has a total feed cost of $1.40 per doe per day, it has a return-over-feed of $1.57 per doe daily. We compare this to a farm with reduced production at 2.5 litres per doe but also reduced feed cost at 95 cents per doe per day, resulting in a return-over-feed of $1.30 per doe daily. This shows even when feed costs are increased, if we have a positive milk effect, we can find increased farm income.

On a 300-doe herd, that example would result in an improved revenue of $2,430 per month or $29,565 annually for the farm, with higher costs but also high daily production. Tracking on-farm return-over-feed helps to determine where investment in different feed products can be made and how to maximize return for maximum economic efficiency.

Keeping track of daily production and on-farm inventory is also a place to help determine whether the farm is meeting its potential. Before dairy animals can be productive, they need to fulfill their maintenance requirements. For milking does, this accounts for 50 to 65 percent of daily intake. Improving production per head per day helps to reduce the cost to produce a litre of milk and helps to reduce the number of animals a farm needs to house.

For example, a farm with a goal of producing 900 litres of milk a day has very different requirements for number of does, depending on production per doe. At 3.3 litres per doe per day, the farm requires 272 does to fulfill the 900 litres per day. At 2.5 litres per doe per day, the farm requires 360 does to fill the same 900 litres. Based on an average feed cost per head per day of $1.29 per doe, this results in a difference of $114 per day in revenue, or roughly $40,000 per year. Setting a production goal ensures milk is being produced efficiently, and return per doe is being maximized. Along with tracking daily production, tracking milk component levels on-farm is essential to maximize profit.

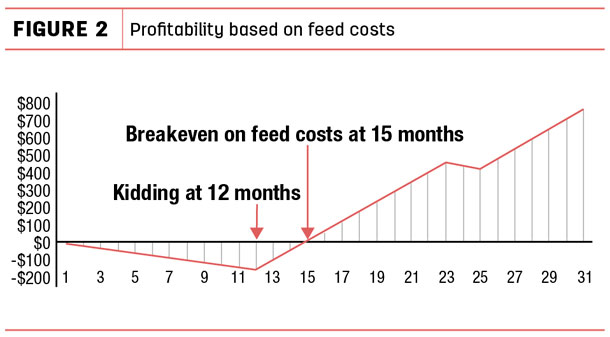

Another key metric is ensuring doelings are reared efficiently and bred on time to maximize their lifetime profitability. Feeding youngstock to ready doelings to be bred at 7 months and kidding at a year improves farm margin. With an average feed cost of 46 cents per doeling a day, it costs $165.60 to get that 12-month-old doeling into the milkline.

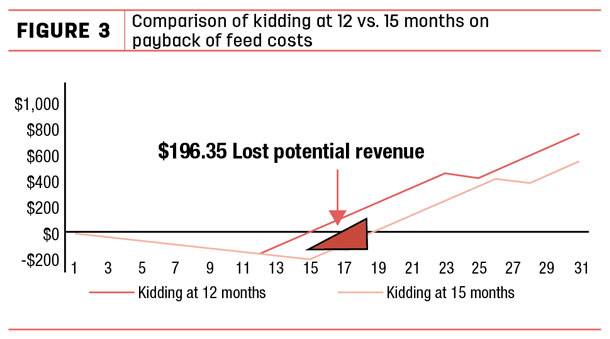

This means, based solely on feed costs, it starts to become profitable at 15 months old. Comparatively, a doeling bred at 15 months doesn’t break even on feed cost until 18-and-a-half months. Both of these examples are based on an average lactating ration costing $1.29 per doe per day.

The delay of age at first kidding by three months ends up resulting in both reduced profitability per doeling as well as 3-and-a-half months of lost potential revenue. Each farm is going to be different based upon how successfully they can raise doelings to appropriate breeding size by 7 months old, but this demonstrates why it should be targeted, and why tracking age at breeding and first kidding can be key to an operation. As well as tracking first kidding, it is important to have effective records to ensure does aren’t receiving extended dry periods.

Due to batch breeding and some does’ propensity to begin drying themselves off once they are pregnant, this can be a challenge – but setting a goal for days dry and tracking that will improve a doe’s lifetime profitability. An extended dry period means the farm will have increased feed costs per dry doe and will need to house more animals in total.

Another area to track is on-farm forage quality and waste. Goats are extremely susceptible to molds, and any spoilage in farm forages can result in decreased production and increased health challenges. Spoilage also results in increased cost to produce milk.

On average, farms using the program are spending 45 cents per day per doe on forage (using standard forage pricing). Therefore, if the farm is experiencing 30 percent spoilage of that forage, they are faced with an increased cost of $14,782.50 annually. That is only taking into consideration feed cost and doesn’t address the other health and production ramifications of the spoilage.

These costs all add up to create a situation where profit is diminished and margin is being lost on-farm. For example, on a farm milking 300 does averaging 3 litres at 90 cents per litre, the annual revenue would be $295,650. If you factor in 30 percent on-farm forage spoilage, 30 percent of doelings being bred at 9 months and 30 percent of dry does having an extended dry period, it results in a loss of $17,416.50 in profit, which is 6 percent of overall total milk revenue.

This is an industry that will continue to develop and, even with current challenges, has the potential to be profitable for producers. However, to reach that potential, it is essential to have a firm grasp of on-farm costs and production targets. Once those metrics are determined, it allows for farms to identify bottlenecks, find opportunities and set effective goals to allow the farm to progress.

In our work on farms, we have found tracking return-over-feed, production level, age at first kidding, dry period length and forage waste are excellent starting points to determine the economic status of the farm and where improvements can be made. Once this is determined, on-going tracking enables producers to ensure goals are being reached and to continue to improve their whole-farm profitability. ![]()

PHOTO: Goats at the feed bunk. Photo by Mike Dixon.

Erin Harris, Dairy Goat Consultant, B-W Feed and Seed Ltd. Email Erin Harris.