Some of these things include chemical fumes such as those from formaldehyde, particulates in the air like sawdust and hazardous gases, especially when working around manure storage.

The worst part of these air quality hazards is: They are unavoidable. So if we cannot stop conducting chores that include sawdust, chemicals and manure storage gases, what can we do to protect our respiratory system?

Air-purifying respirators (APRs)

The activity you are doing will determine the type of respirator you will need for proper protection. If you are working in an area where there is a good supply of oxygen, such as in a barn, an APR will likely be the right choice.

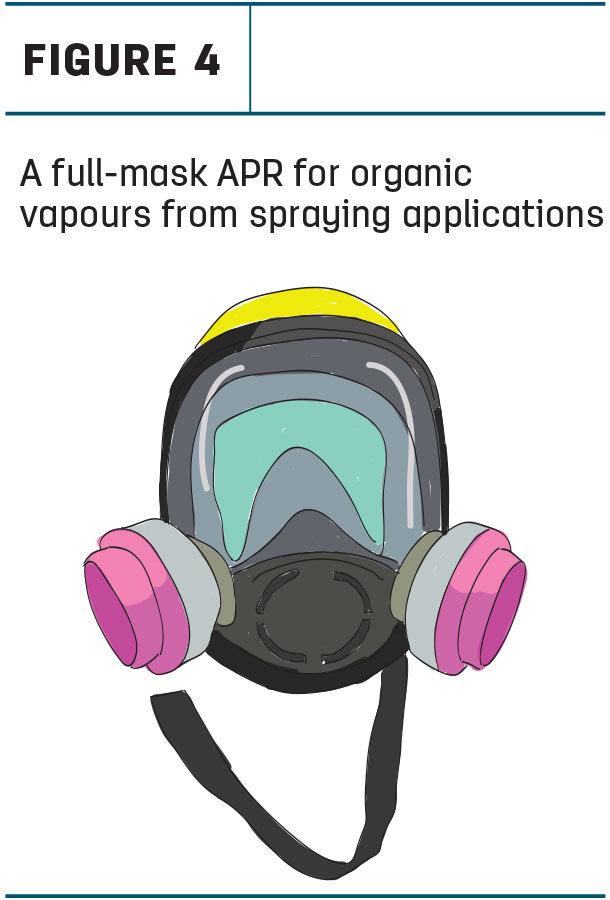

An example of an environment where this would not be suitable is a manure pit. APRs clean the air of contaminants, using filters or cartridges, and typically cover the mouth and nose (half mask) or the entire face (full mask). The one most suitable will depend on the task at hand and hazards present.

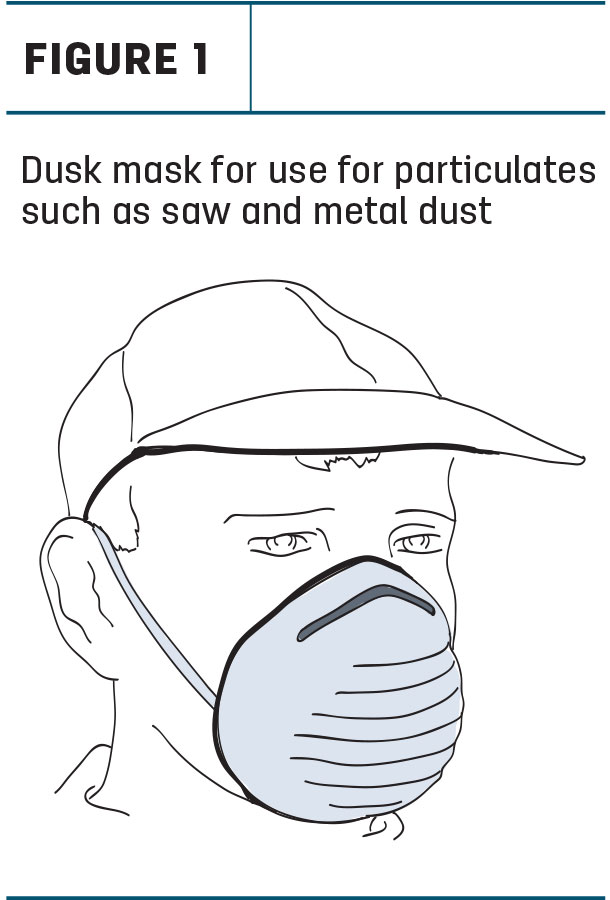

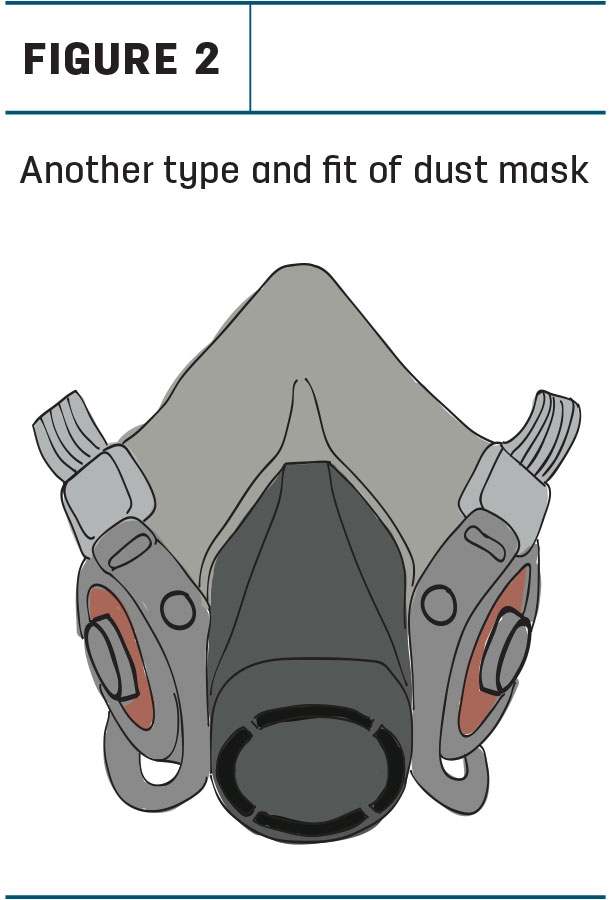

One type of APR is for particulates in the air. This is typically a filter-type mask, known as a dust mask. However, there are also other styles which provide a tighter fit on the face and are better for use depending on the task at hand (Figures 1 and 2).

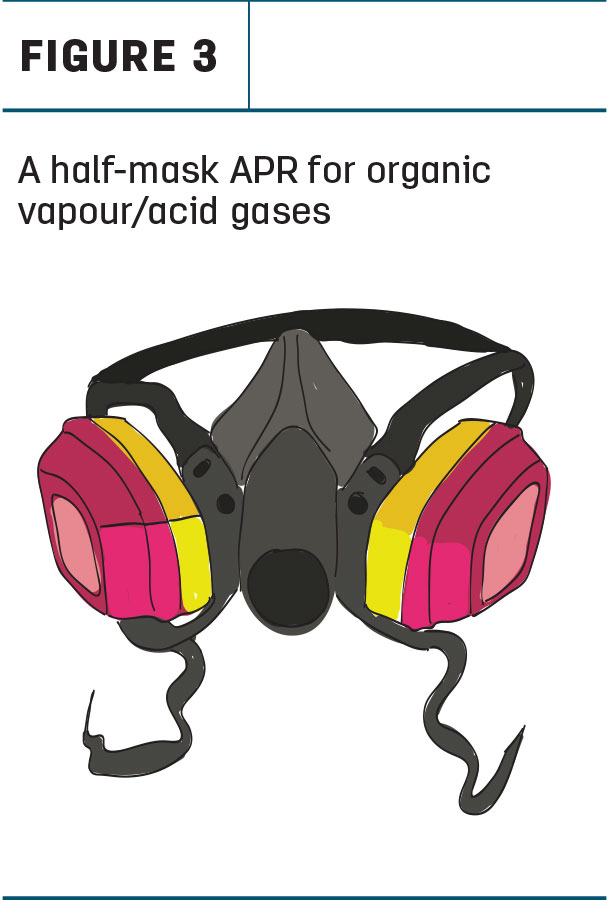

There are also APRs that have cartridge or canisters as the air-purifying measure, which purifies the air by absorbing the gas or vapour from the air into an absorbent material.

The proper absorbent material to use is different depending on the gas or vapour in the air, such as an organic versus a chemical gas or vapour (Figures 3 and 4).

When determining which respirator to purchase, be sure to read the label thoroughly to know if you will be protected from the hazard you are dealing with.

To determine exactly which respirator to use when dealing with a specific chemical, always consult the safety data sheet (SDS) for the chemical. These types of respirators can be purchased from many retail outlets as well as safety supply manufacturers.

Atmosphere-supplying respirators

This type of respirator is what you would use when working in an oxygen-deficient environment, such as a confined space. The type of supplied air respirator intended for use while working in an oxygen-deficient environment (rather than for emergency rescue purposes) is called a self-contained breathing apparatus (SCBA).

SCBAs offer the best protection for producers and employees on the dairy who are entering oxygen-deficient areas or other atmospheres immediately dangerous to life.

SCBAs have either an open-circuit or closed-circuit design. The closed-circuit design involves a re-breathing device. The open-circuit SCBAs expels the exhaled air into the atmosphere instead of recirculating it.

With this system, a full-face mask and oxygen tank provide safe and oxygen-filled air to the user. These types of respirators can be purchased from your local safety supply manufacturer.

You have the right respirator, but does it fit right?

Proper fit is vital to a respirator’s ability to protect you. Just think, what’s the point of wearing one if all of the gases, vapours and dust are getting in anyway?

To this point, and for the purpose of sanitary masks, each wearer on your dairy should have their own respirator. Here are two quick ways to ensure proper fit:

1. For a positive fit check, cover the exhalation valve with the palm of your hand and exhale so air builds up inside the respirator. If there is a leak, you will feel it against your face.

2. For a negative fit check, cover the cartridges with both of your hands and inhale. If there is no leakage, the mask will be drawn tightly to your face like a suction cup.

Maintain your respirators

The last step is to make sure your respirators are always ready for use. Carefully read and follow the manufacturer’s instructions for maintaining the respirators you have on your dairy. Follow a regular schedule for replacing filters or cartridges or canisters, based on how often you use them.

Before each use, do a quick check to ensure the respirator will be good for use; take a look at the following:

- Excessive dirt around the face piece

- Detergent residue

- Missing valve covers

- A cracked face piece

- Breaks, tears or loss of elasticity in the head straps

Most importantly, never attempt to repair a damaged respirator beyond replacing the replaceable parts, such as filters and head straps. Last, store respirators in a safe, clean location.

By following these steps to ensure the proper selection, fit and upkeep of your respirator and those of your employees and team members, you will be doing your part to reduce the hazards in the air for yourself and your team at your dairy. Your lungs will thank you. ![]()

-

Danielle Pasztor

- Farm Safety Specialist and HR Consultant

- PeopleManagement Group Inc.

- Email Danielle Pasztor