It works in conjunction with the six automatic milking system units at the 335-cow dairy owned by Gerhard Ritzema of Seaforth, Ontario.

Along with his wife, Heather, and two young sons, Ritzema brought robotic technology to their dairy in 2013. The cows average 10,750 kilograms of milk per day with 4.2 percent butterfat, and they are housed in a six-row freestall barn with drive-through feeding and a free-flow traffic system.

Taking the next step to incorporate milk analysis with his milking system means he has a series of daily and weekly reports available at his fingertips to guide his breeding and treatment decisions.

“I don’t do anything with a cow before looking at [the reports],” Ritzema says.

A new routine

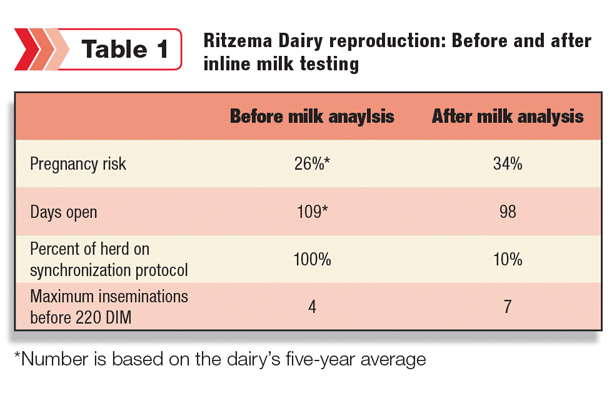

The technology has changed the way Ritzema manages his reproduction routine. In the past, he maintained a 26 percent pregnancy rate using an Ovsynch protocol across the milking herd. While he admits he was hesitant to make changes to this program for fear of that number decreasing, just the opposite happened. Now, by making breeding decisions off of his reports, pregnancy rate has actually improved to 32 percent.

Changes in milk progesterone trigger the system’s heat alarms and “cows to breed” report. Ritzema can then view a graph of the individual cow’s hormone levels to determine when to breed her for the best opportunity for conception.

“Before, a cow could be in heat but not have the level of progesterone to get pregnant,” he says.

This has helped Ritzema hit new benchmarks for reproductive efficiency. Fifty percent of the cows are now pregnant at 83 days in milk (DIM) compared to 105 DIM in the past, and 70 percent are confirmed with calf at 104 DIM, which is 45 days sooner than before.

More precise breeding, based off of milk progesterone levels, has not only reduced days open but also decreased reliance on synchronization. These days, only cows that are anestrous or cystic receive hormone shots, which equates to less than 10 percent of the herd.

On a weekly basis, Ritzema reviews reports denoting cows with luteal and follicular cysts, and he cross-checks the list with his herd management records.

In addition to measuring progesterone, the milk analysis also produces a daily report on beta-hydroxybutyrate levels as an indicator of ketosis. Ritzema is using this information for early metabolic disease intervention by implementing drenching as part of the daily protocol for cows that show up on this list.

While reproduction and ketosis have been his leading applications, Ritzema is also learning how to make use of the system’s mastitis report. It allows him to track chronic cows and target antibiotic use.

It’s payback time

Ritzema estimates his investment in real-time milk analysis technology will pay for itself in seven years. This is based on a cost per cow per year of $207 and considers a net profit of $62 for improving pregnancy risk and $98 in reduced veterinary costs per cow per year.

He also finds value in having accurate information to make profitable culling choices. Keeping older cows in the herd longer means more milk in the tank. “Now I can make decisions on which cows I need to keep around,” he adds. “An older cow gives more milk than a heifer.”

In fact, one-third of the herd is in their third lactation or greater. This opens up an income stream from replacement heifer sales. By selling 10 extra fresh heifers each year, he gains an additional $47 per cow. PD

Ritzema was a featured dairy producer at the 2015 Precision Dairy Conference held June 24-25 in Rochester, Minnesota.

PHOTO: Gerhard and Heather Ritzema manage more from reports than ever before. A new inline milk testing system helps them monitor estrus, ketosis and mastitis for each cow. Photo by Peggy Coffeen.