Technology continues to push the dairy industry forward with bigger, better, more automated equipment – yet some old reliables are making a comeback. Manure gutter cleaners have existed for more than 60 years. They have stood the test of time thanks to their reliability, heavy-duty build and ability to adapt to changing farm needs.

While their general design remains the same, their application has evolved with the times. Here’s a look at how and why manure gutter systems have become popular again.

Making a comeback

Early manure gutter cleaners ran behind cows in traditional tiestall or stanchion barns. While tiestall and stanchion barns are no longer the norm, GEA has experienced a 10 percent increase in barn cleaner installations in the last three years. Why? This comeback is largely the result of three factors: housing, bedding and water.

Housing

The evolution of cow housing and the rise of robotic milking have made an impact on how manure is collected. Manure removal in robotic barns becomes even more challenging because the cows are always in the barn. This change results in more individual manure piles spread throughout the barn, compared to early barn designs where most manure went directly into a gutter.

To accommodate this change, many barns incorporate a gutter cleaning system that runs perpendicular to the manure alleys. Automatic alley scrapers or flush systems clean the barn and push manure into the gutter. The cleaning system then automatically moves the manure into the manure pit. Often the manure is then transferred to a lagoon via a piston pump, completely automating the manure removal process.

Bedding

Sand continues to be the go-to choice for bedding, while straw and sawdust use declines. Sand is great for cow comfort, but it’s not absorbent like other bedding materials, making manure consistency more liquid. Some manure scraping systems funnel water and, in some cases, manure into a channel down the alley. Using a channel system helps dry out the manure and reduce the volume, making it easier for the scraper to handle.

Water

In the past, water was a popular way to help move manure. While some farms still use flush systems, there’s a growing trend to use less water in manure removal for conservation and sustainability benefits. However, less water means manure consistency is drier and more difficult to move. Gutter cleaning systems can easily handle drier manure compared to other manure removal systems.

What’s changed

While deemed an old reliable, a few advancements have been made to manure gutter cleaners over time.

Control technology

Technology for controlling early gutter cleaners was minimal, at best. Farmers would turn the cleaner on and then go out and do chores while it ran – hopefully remembering to shut it off before going home.

Today’s technology advancements give farmers more control. Gutter cleaner systems are now equipped with automated timing capabilities. For instance, when a gravity-assisted scraper system dumps manure into the gutter, proximity switches or timers will automatically turn the gutter cleaner system on as soon as the manure starts dumping. Timing can also be adjusted to synch with parlor discharge water to rinse the gutter.

Improved safety

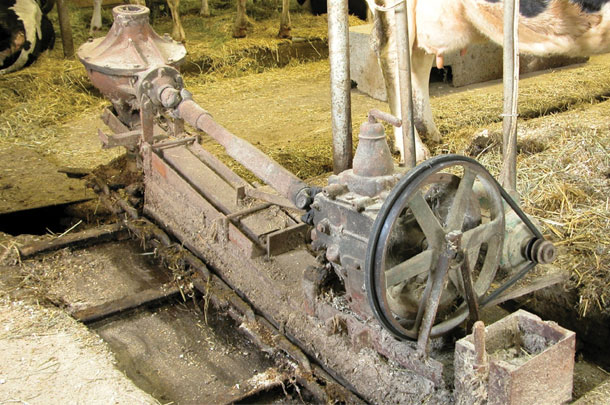

Early gutter cleaning systems had many moving parts where farmers could easily get injured. The simple addition of a cover for the drive unit has greatly reduced safety risks. Locking down the covers and adding single-point greasing made gutter cleaners even safer. These new safety measures keep farmers from being exposed to moving parts during maintenance.

Design changes

Only minor changes have been made to the design of manure cleaner systems. The main changes include gearbox and motor improvements. Chains have also been made bigger and more durable to adapt to longer barns and sand bedding. Traditional systems used an elevator to stack manure outside of barns. Thanks to changing manure consistency, elevators are no longer needed like they were for traditional systems.

As the dairy industry continues to evolve, so will the use and application of manure gutter cleaners. After all, you can always count on an old reliable. ![]()

-

Jeramy Sanford

- Global Product Manager of Manure Equipment

- GEA

- Email Jeramy Sanford

PHOTO 1: Many gutter cleaning systems transfer manure to a pit. Often the manure is then transferred to a lagoon via a piston pump, completely automating the manure removal process. This Electromix system features a pump and agitator.

PHOTO 2: Locking down drive unit covers and adding single-point greasing has made gutter cleaners even safer.

PHOTO 3: Early gutter cleaning systems had many moving parts where farmers could easily get injured.

PHOTO 4: Many of today’s dairy barns incorporate gutter cleaning systems that run perpendicular to the manure alleys. Photos courtesy of GEA.