Tibben Farms also encompasses a 200-head farrow-to-finish hog operation, which is operated by Ralph’s brother, Bill Tibben, and his son, Glen. The two operations work in tandem with their feeding programs.

“One of the advantages of having the hog farm as part of the operation is: We are able to coordinate our commodities with what they use. They buy everything in bulk, and they’ll premix for us,” Mike says.

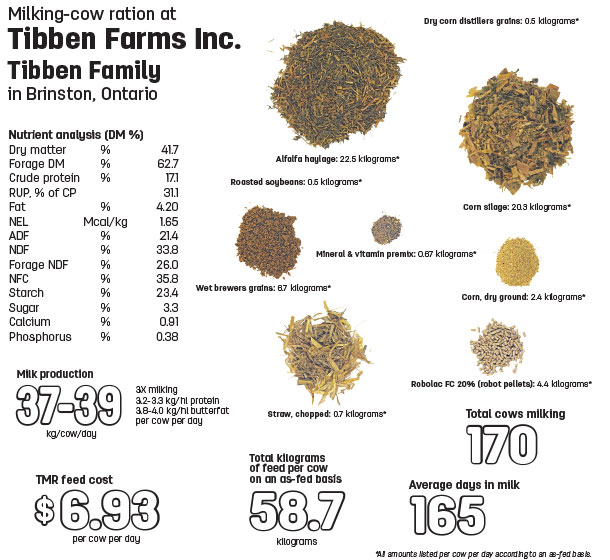

Once a week, the premix, consisting of corn distillers, soybean meal, roasted beans and dry corn, is mixed by the hog farm and delivered to the dairy.

“When we do the cow mix, we’re just adding that one batch, as opposed to individual ingredients a little at a time. There is so much more precision and definitely less waste,” Mike says. “By splitting it with the hog operation, it’s a pretty efficient way to do it time- and cost-wise.”

With only a few ingredients, it speeds up the time spent mixing feed each morning. The rest of the ration fed in the bunk is BMR corn silage, alfalfa haylage and a little bit of straw for effective fibre when the forages are a little too wet. The farm’s 180 cows receive the rest of their ration when visiting any of the three milking robots.

“We definitely have more control over our feeding now with robots feeding each animal individually,” Mike says. “Before, we had a fresh cow group and we fed one main TMR to everybody else. There was a lot of overfeeding to the late-lactation cows and underfeeding of the higher-producing cows.”

The partially mixed ration (PMR) fed at the bunk is balanced for 25 kilograms of milk. Then the farm’s nutritionist decides the amount of pellet to be fed in the robot. It is entered into a feed table, and the computer takes care of the rest, Mike says.

“There’s a lot of flexibility in that program so you can really tailor to specific animals,” he adds.

Margaret Currie, dairy specialist, Grand Valley Fortifiers Ltd., is the representative that visits the farm every week to 10 days. She is the eyes and ears to pass back farm information to the office for proper ration formulation.

Currie says, “We typically run (at Tibbens) a ration that is balanced lower than what’s typical for the PMR in the bunk to get the cows going to the robot. Our ration is unique in that we pride ourselves in having a very low to little fetch list with the robot herd. That’s all through how we balance the ration.”

Mike reports the farm also has few, if any, incidences of ketosis. They give all of the cows a monensin bolus three weeks prior to calving and then feed an additional fresh cow pellet through the robot two weeks postfresh for cows and three weeks for heifers.

Mike says he will extend that feed longer for any animal that might need it based on components and overall production.

As the number of cows at Tibben Farms continues to increase, Mike says they now must feed a third mix in the afternoon. “We’ve definitely seen a production boost from that,” he says. “Even if you make the mix in the morning and unload it later in the day, it’s well worthwhile.”

In seeing those results, as well as research done on frequent feedings, the brothers recently opted to switch to an automated feed system to mix and deliver feed throughout the day.

“With the robotic barn, we don’t depend on hired help anymore. It’s just the three of us, with 180 cows milking and Mark cropping 2,500 acres. We’re trying to keep everything as efficient as possible. By not having to manually make the mixes, that will free up up to three hours a day,” Mike says.

With the change to an automatic system, the farm is abandoning the bunk silos it has used for the past 20 years to capture the automation offered with upright silos.

“The tower silos were a better fit for a fully automated system than the bunks,” Mark says. However, that transition brought about a need to put up dryer feed, which the farm is accomplishing in a number of ways.

According to Mark, they’ve added more grasses back into their alfalfa fields to help speed up drying. This also helps them find a better balance between yield and quality.

“In the event of threatening weather, we have a better opportunity that if we cut one day, we can harvest it the next. We’ll be able to get off the crop when it needs to be harvested versus going too early and sacrificing yield or getting caught and having to wait too long, sacrificing quality,” Mark says.

To get a good alfalfa stand, Mark starts with high-quality, certified seed. “In some of the newer alfalfa varieties, the standability of them and the regrowth is far above what they were 10 to 15 years ago,” he says. “Some of these aggressive varieties now, in our climate, can handle four cuts no problem and still have lots of time for their fall dormancy period.”

The grasses are also more aggressive these days. He has added orchardgrass and festulolium into his mix and is seeing a nice blend of grasses in each cutting.

Mark has started to rotate his forage crops more often. Traditionally, he would have kept a stand for four years. Now he aims to take off three cuttings in the establishment year, keeping it for two years after that and then rotating the field.

“Quite often, you see too many hayfields that are past their productive lifespan, and it’s 50 percent dandelions growing in it,” he says. “You’re better off to rotate that field into something else and plant a new one.”

To increase yield in the seeding year, they don’t use a cover crop but instead direct-seed the alfalfa mixture with a seed-placed starter fertilizer.

“From what we’ve seen this year, in our worst drought year in 32 years, we pulled off remarkable yields off of our new seeding. I like to think that we’ve passed that 50 percent point and we’re getting 60 to 70 percent of the yield of an established stand off of our new seeding. That’s exciting and promising,” Mark says.

At harvest, he uses GPS and autosteer for mowing and merging. He also avoids driving over the forage after it has been cut to avoid packing it down into the soil. This allows him to run the merging equipment higher, reducing soil contamination.

He also modified a lot of the farm’s haying equipment to take advantage of wide-swath haylage. “We found that a lot of the mowers, when we purchased them new, they windrowed the hay too much, and we made some changes to lay things out wider and maximize the drying that way too,” he says.

Excellent forage production benefits the farm as a whole. “We want high-quality forage for the milk cows, but I also want to grow crops that are beneficial for the health of our soils,” Mark says.

“A lot of people in our area have strayed away from the forage crops – alfalfa and grasses – but I remain committed to keeping that in our crop rotation and using them as a forage crop,” he adds.

From forage to feeding, the Tibben family has found ways to expand its efficiencies for high production in the field and barn. ![]()

-

Karen Lee

- Editor

- Progressive Dairyman

- Email Karen Lee