The data presented in this article was collected on six farms in Quebec and two in Ontario.

Composting conditions and process

During the composting process, micro-organisms break down organic matter to produce carbon dioxide, water and heat. In a compost-bedded pack barn, the manure, urine and added bedding are sources of essential nutrients required for good composting.

The process also requires a continual supply of the right proportion of oxygen, carbon and nitrogen, which means the bedded pack must be aerated regularly.

The heat generated by the composting process will be sufficient to keep the resting surface dry and control pathogens, fly larvae and weed seeds.

When the pack is composting properly, the surface will look fluffy and dry. When composting is inadequate, however, the bedding material will look damp, and clumps will form.

While the surface temperature of the bedded pack is generally close to the ambient temperature, the temperature under the cows tends to be higher.

The effectiveness of the composting process can be evaluated by measuring the pack temperature at a depth of 15 to 30 centimetres (6 to 12 inches). Ideally, the temperature should be between 45 and 60ºC. If the temperature rises above 65ºC, the bedding surface may become uncomfortably hot for the cows.

Higher temperatures are an indication the organic matter is decomposing very rapidly and may destroy beneficial bacteria. Lower temperatures, on the other hand, may indicate a lack of oxygen due to inadequate aeration, excess moisture or excessive heat loss in winter. A moisture level between 45 and 55 percent is recommended to ensure proper composting.

Ideally, the carbon-to-nitrogen ratio should be between 25 to 1 and 30 to 1. An ammonia odour may be present if the carbon-to-nitrogen ratio drops below 25 to 1 or if the pack contains too much manure in relation to bedding material.

Keys to success

With an understanding of how the compost process works, here are six keys to maintaining a successful bedded pack barn.

1. Space

To sustain the composting conditions, it is important to maintain a good balance between animal waste and bedding material. In Quebec and other similar conditions, a pack area of 140 square feet per cow is recommended.

2. Bedding

Different types of bedding are used in compost barns. When using straw, it is important to make sure it is finely chopped to facilitate its decomposition by bacteria and dry to maintain an optimum moisture level in the pack.

When sawdust bedding is used, it is important to consider the type of wood. Resins from coniferous species contain bactericidal chemical compounds that may inhibit bacterial survival and therefore reduce the effectiveness of the composting process.

Deciduous or hardwood species are thus preferred for bedding materials.

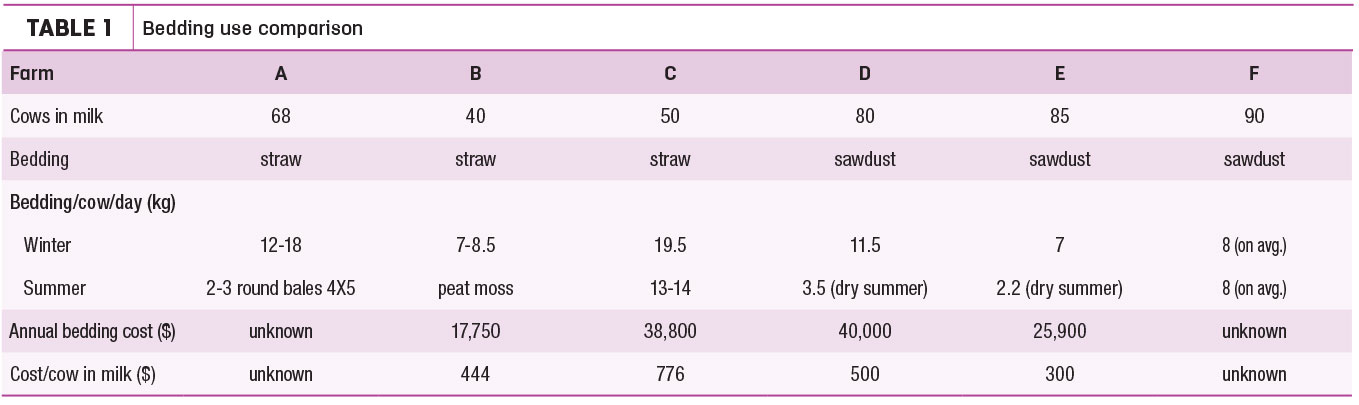

Table 1 presents the different quantities of bedding used on the farms visited as part of the survey.

While there is clearly an enormous amount of variation, this system generally requires more straw than sawdust. Even among farms using sawdust, the quantities used varied.

These differences are attributable in part to the dry matter content of the added materials, the type of barn (cold or insulated) and the level of ventilation (ambient relative humidity).

The quantities of bedding material required decrease considerably during the summer months, especially if conditions are dry. Advantageously, bedding requirements drop even further for herds on pasture.

3. Pack management

Since composting requires oxygen, the pack must be stirred twice daily to ensure adequate aeration. The size of the equipment used varies somewhat, but the pack is generally cultivated to a depth of 30 to 45 centimetres (12 to 18 inches).

To obtain a more uniform surface, it may be necessary to alternate between deep cultivating and tilling the surface material to break up the clumps.

The farms using sawdust bedding and one of the farms using straw generally added bedding materials twice a week. One of the farms visited uses an old manure spreader to add sawdust. The two other farms using straw added bedding more frequently at twice a day.

Cleaning of the bedded pack varies greatly from one farm to the next, depending on how it is used in the fields.

When removing the pack material, it is important to leave some of the soiled bedding in the barn to restart the composting process after adding new bedding.

Peat moss is sometimes used in the summer to replace the compost-bedded pack because it is cooler for the animals.

4. Ventilation

A considerable amount of moisture and gases escapes the pack during stirring, and a haze often obscures visibility for 15 to 20 minutes. A good ventilation system is therefore essential to evacuate moisture and gases from the building.

It is also important to take into account the heat generated by the composting process. In a study conducted in 12 compost dairy barns in the U.S., it was shown cows spend less time lying down when the temperature-humidity index exceeds 72.

Hence, it is important to be able to alleviate heat stress in order to maintain milk production during hot weather.

Ventilation must also be optimized to ensure adequate air exchange throughout the building. If ventilation is deficient, cows may choose to lie down together in a wetter area where air quality is better rather than on a dry surface where the air is stale.

5. Economic considerations

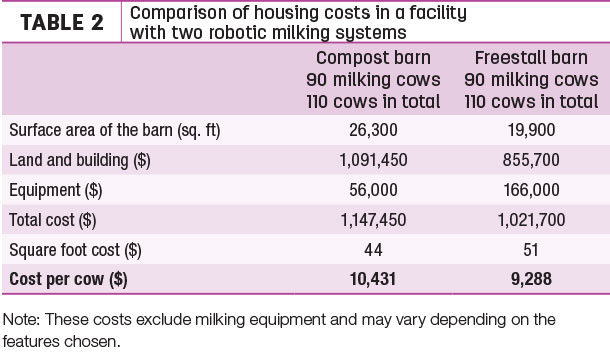

Table 2 compares the construction costs of two types of housing – a freestall barn and a compost barn – for an insulated facility with two robotic milking systems.

(The cost of the robots was not included in this estimate, as the aim was to compare only the construction costs. The costs will vary depending on the features and equipment chosen.) The comparison was also done for a milking parlour facility, and the square-foot cost of construction was similar, although the difference in cost per cow was slightly lower.

Because a compost-bedded pack system requires more space, the total cost of the project is higher than that of the freestall project, even though the square-foot cost is lower.

Therefore, it makes more sense to compare the facilities on a cost-per-cow basis, giving an overall difference of about $1,000 per cow, between the two types of housing.

Recurrent costs also differ. Since tractors get more use in a compost barn than in a freestall barn, fuel costs will be slightly higher, depending on the extent of use (aerating, frequency of bedding addition and feeding).

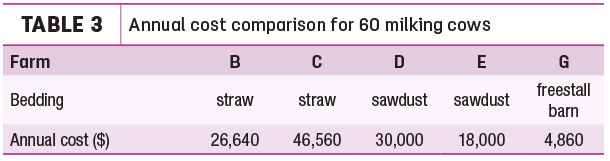

The most significant of the variable costs is bedding material. Table 3 shows the costs of the four farms using a comparable basis of 60 cows.

The cost of sawdust varies between $130 and $142 per metric tonne while the standard cost of straw is $150 per metric tonne.

Compared with a freestall barn, a compost barn will require three times more bedding when all is going well, and more if conditions are not ideal.

Besides additional expenses, there are some other aspects that must be included in the equation when looking at this type of housing and its overall effect on the operation:

- Increased cow comfort means lower replacement costs

- Lower manure spreading costs

- Reduced soil compaction

- Less investment in storage facilities (in some cases)

6. Animal health

When considering a compost-bedded pack system, udder infections are the main health concern. The dairy operations in this study observed no deterioration of milk quality after they switched to the new housing system.

When the moisture content of the bedding pack is higher, however, they may see a rise in the number of infections. It is possible to produce good-quality milk in a compost barn, but the composting process must be carefully managed.

With regard to feet and legs, data on digital dermatitis was available from four farms, but data from before the change in housing was not available from all farms for comparison. The number of cases of digital dermatitis varied from zero to three per year for 60 cows.

Only one of the four farms used preventive footbaths on a weekly basis, and this farm had no feet and leg problems. The literature on bedded pack systems also mentions this type of housing improves foot and leg health, with three times fewer cases of lameness in the herds studied and a lower incidence of hock lesions.

Conclusion

Farm visits are the best way to sort out the pros and cons and get an accurate picture of the situation.

Some of the comments noted during the visits to the farms in this survey include cow comfort and its effect on longevity (topped the list of benefits mentioned), lower storage costs (where applicable), easier manure management and lower spreading costs.

Others also mentioned the reduction in odours during spreading as an advantage. In terms of disadvantages, both the supply and cost of bedding materials were mentioned, in addition to dust generated during straw chopping, and fuel costs, depending on machinery use.

Housing cows on compost-bedded pack is definitely a worthwhile choice for improved cow comfort and longevity, but it requires paying close attention to compost management and budgeting for some additional costs. ![]()

PHOTO 1: When managed correctly, compost-bedded pack barns, like this one at Swisskess Farm, St-Georges-de-Clarenceville, Quebec, offer better comfort and hoof health for cows. Photo courtesy of Swisskess Farm.

PHOTO 2: Cultivating the pack to a depth of 30 to 45 centimetres (12 to 18 inches) helps introduce oxygen to continue the composting process.

PHOTO 3: Tilling the surface is an option to create a more uniform surface, but deep tillage must continue to be done on a regular basis. Photos courtesy of Valacta.

Steve Adam is an agronomist with Valacta and an expert in cow comfort and animal behaviour and well-being. Email Steve Adam.

References omitted but are available upon request. Click here to email an editor.

-

Valérie Martin

- Strategic Adviser

- Valacta

- Email Valérie Martin