There is a certain appeal in feeding long dry hay to dairy cows, especially because the cows seem to gravitate to this type of forage, but is this the best way to feed dairy cows? Historically, long dry hay has been associated with improved cud chewing behaviour and a subsequent improvement in rumen health – but is this a real association?

To better understand the impact of particle size on cud chewing and rumen health, we need to fully understand rumination. Although rumination is often equated with cud chewing, it is actually a more complex process. Rumination consists of three main activities that each need to be understood:

- Eating

- Cud chewing

- Rumen contraction

Eating and particle size

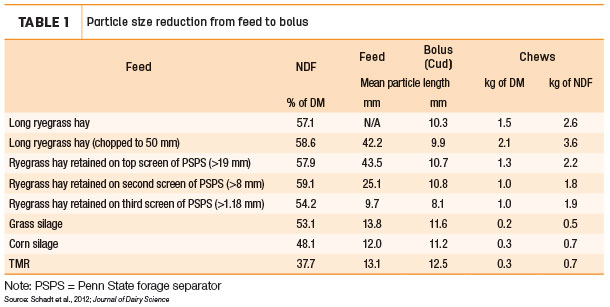

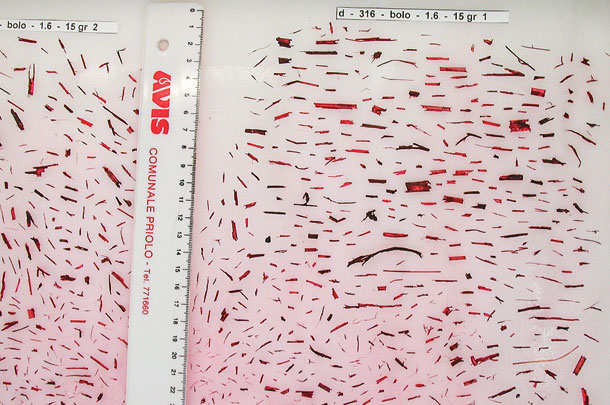

The dairy cow uses a grinding action with the molars to reduce the particle size of the forages – resulting in a shearing effect rather than cutting. This is critical because the material needs to be reduced in particle size to be swallowed and then regurgitated as a bolus (cud). Innovative research by Italian researchers demonstrated that the dairy cow, during eating, chews the forages just enough to reduce the forage particle size to be able to swallow the bolus – no more, no less. Longer or poorer-quality material would increase eating time due to the increased difficulty in reducing particle size. The Italian research demonstrated that, regardless of the particle size of the ingested material, the particle size of the regurgitated bolus (cud) remained similar (see Table 1 and Photo 1).

Photo courtesy of Iris Schadt, Ph.D. researcher at CoRFiLaC, Ragusa, Sicily, Italy.

Photo courtesy of Iris Schadt, Ph.D. researcher at CoRFiLaC, Ragusa, Sicily, Italy.

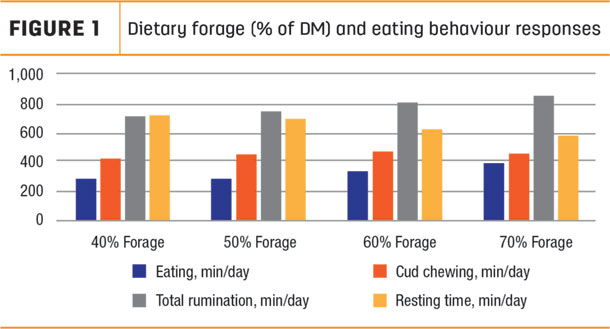

Recent research has shown an inverse relationship between time spent eating and resting. Long material, such as long dry hay, increases eating time but may reduce resting time – depending on the quality of the forage. Researchers in 2017 compared diets with increasing levels of forage, from 40% forage to 70% forage (Figure 1).

As the forage content increased, peNDF and uNDF240 levels also increased. There was a significant increase in rumination time (eating and cud chewing), largely through an increase in eating time. This resulted in a decrease in resting time that reflected the increase in total rumination time.

Why is this important?

Analysis from the Miner Institute in 2007 identified a relationship between resting time and milk production: Each hour increase in resting time resulted in a gain of 1.7 kilograms (3.7 pounds) of milk production.

Poor-quality forages (higher uNDF240) may increase eating time due to the inherent difficulty in reducing particle size, while high-quality forages (lower uNDF240), due to the potential fragility of the plant, may break down more quickly – thus reducing eating time.

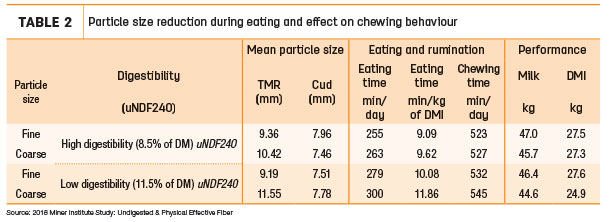

A study conducted at the Miner Institute examined the digestibility of the diet (uNDF240) and the physically effective fibre in the diet (peNDF and peuNDF240). The study examined four diets that contained the same amount of corn silage and chopped wheat straw. The particle size and uNDF240 content were adjusted using timothy hay at two chop lengths and some pelleted beet pulp to further reduce uNDF240. Table 2 shows that cows on the high-digestibility/low-effective fibre treatment had approximately 45 minutes less eating time but consumed over 2.26 kilograms more feed as compared to the low-digestible/high-effective fibre diet.

The animals on the low-digestible diet (high uNDF240) with the longer timothy hay spent more time eating to reduce particle size and more time chewing due to the structure of the fibre. There appears to be an intersect between forage quality and particle size with potential for improved milk performance when lower-quality forages are chopped finer. This study also demonstrated that the particle size of the bolus (cud) was very similar between diets, regardless of the particle size of the forages.

Cud chewing and particle size

Cud chewing is a critical component of the rumination process because it allows the dairy cow to access the nutrients locked within the forages. The majority of cud chewing is done during the resting period for the cow – when the cow is lying down.

Cud chewing allows the dairy cow to add moisture to the forages through particle abrasion and saliva production. The rumen microbiota require the feedstuffs consumed to become moist to allow for attachment and to initiate the digestion process. Drier feedstuffs need to reach approximately 50% moisture content to aid in microbial attachment.

As previously noted, the particle size of the forage is reduced through the eating process. Cud chewing abrades the fibre particles through a grinding action that is crucial for bacterial attachment. Research from 2018 states that “rumination (cud chewing) – not eating – is the principal means by which feed particles are decreased in size by dairy cattle.”

Bacteria are opportunists and seek out the most rapidly available nutrient source; they quickly attach to the cut end of the forage particle. Ruminal bacteria attach to cells on the inside of the fibre and digest towards the outside until they are inhibited by a lignified wall. A thin lignified residual wall always remains, even after extremely long rumen exposure times.

The rumen bacteria can easily attach to the cut end of the forage particles but have difficulty attaching to the outside wall, partially due to an impermeable waxy coating. This waxy coating is a defense mechanism for plant survivability through improved water retention and lower water loss. This is especially important during drought situations but also increases with maturity. Fungi, another key group within the rumen microbiota, have the ability to penetrate the outside wall of the plant and start the digestion process. This degradation of the outside plant wall structure through fungal digestion will allow for adhesion of primary bacterial colonizers – but this is a slow process. Cud chewing will quickly improve attachment by abrading the fibre and allowing the bacteria to enter the plant cells.

Increasing particle size of the diet seems to have less of an impact on cud chewing time but more of an impact on eating time. Researchers in 2018 reported that “increasing particle size of silage increased eating time (minutes per day and minutes per kilogram of DM) of dairy cows in many studies but not all.”

Decreasing particle size of the diet may have more of an impact on cud chewing than increasing particle size. The regurgitation of the bolus (cud) occurs as a result of a contraction of the reticulum. Small particle size may not elicit the tactile response in the reticulum to contract and regurgitate the cud. Small particle size may also decrease cud chewing by increasing passage rate of the material and subsequent exit from the rumen, leading to reduced ruminal fibre digestion. Fibre that exits the rumen “untouched” is primarily lost to further digestion in the hind gut and will eventually pass into the manure.

Rumen contraction and particle size

Rumen contractions usually occur one to three times per minute, with the highest frequency occurring during feeding and the lowest when the animal is resting. There are two main types of ruminal contractions: primary contractions and secondary contractions. The primary contractions originate in the reticulum and then pass around the rumen. The secondary contractions occur in the rumen and are associated with eructation. Rumen contractions are stimulated by tension (mechano-) receptors in the reticulum and rumino-retucular fold. The tension receptors require pressure or a tactile stimulation from fibre to initiate the contractions.

Primary ruminal contractions are critical to mix the contents of the rumen. This allows for improved digestion through moistening of the feedstuffs and improving the ability of the ruminant to regurgitate a bolus. Feed that is too fine may lead to ruminal acidosis with a resulting reduction in rumen motility with less primary and secondary contractions.

Practical recommendations for particle (TLC) size of forages

Applying the “Goldilocks principle”

The term “Goldilocks diet” is often used when referring to the high-straw, controlled-energy diet for the dry cow. The attribute of this program is: It is incorporating just the right amount of energy – not too much and not too little.

The Goldilocks principle can also apply to length of cut at harvest or particle size – not too short and not too long, but just right for optimum performance.

Particles that are too long can potentially lead to an increase in eating time, which could lead to a reduction in resting time. As discussed earlier, reduced resting time has been associated with reduced milk production. The compelling issue with long particle size is the increased risk of sorting behaviour that discriminates against the longer forage components.

Sorting against long particles can lead to rumen health concerns such as subacute ruminal acidosis (SARA). This can be exaggerated with diets that are high in starch and low in NDF or if there is competition at the bunk due to poor feeding management or overcrowding.

Particles that are too short may lead to reduced rumen motility, increased incidence of SARA and high passage rate of the forage particles. Post-ruminal fibre digestion (hind gut) is negligible – this represents a lost opportunity for deriving nutrients from fibre in the rumen. Retaining the forage particles in the rumen environment will improve forage digestibility.

What are some trends we are seeing with particle size?

Producing very fine corn silage has been adopted in different regions around the globe. In parts of Europe, there has been a trend to reduce the particle size of corn silage through TLC (theoretical length of cut) harvesting at 5 to 10 millimetres (0.2 to 0.4 inch).

Why is this practice popular?

Many producers believe that:

1. Fine chop produces extensive kernel damage, thus decreasing the reliance on proper kernel processing.

2. Fine chop will improve packing density in the bunk.

3. Fine chop will improve packing density and fermentation when harvesting drier corn silage (greater than 40% DM).

In many scenarios when producing fine corn silage, the haylage (grass and alfalfa) has been increased in particle size to compensate. This leads to a less homogenous TMR and potential for an increase in sorting behaviour. The finer particle size can also lead to increased passage rate and the potential loss of digestible fibre in the corn silage.

But what does the research say?

A meta-analysis of corn silage harvesting practices was published in The Professional Animal Scientist. The meta-analysis reviewed 24 scientific papers and examined the impact of corn silage harvest maturity (dry matter content), kernel processing and length of cut on DMI, digestion and milk production.

The results were surprising.

In this meta-analysis, the TLC was categorized as:

- 4.8 to 6.4 millimetres (0.19 to 0.25 inch) – short/fine

- 9.3 to 11.1 millimetres (0.37 to 0.44 inch) – short/fine

- 12.7 to 15.9 millimetres (0.5 to 0.63 inch) – typical North American range

- 19 to 19.5 millimetres (0.75 to 0.77 inch) – typical North American range

- 25.4 to 28.6 mm (1 to 1.13 inches) – long

- 32 millimetres or greater (1.26 inches) – long

The length of cut (particle size) of the corn silage had very little impact on any of the production and digestion parameters.

- DMI was unaffected (P = 0.68) by length of cut.

- Milk and milkfat were unaffected by length of cut.

- Diet dry matter digestibility (P = 0.69), organic matter digestibility (P = 0.93) and NDF digestibility (P = 0.74) were unaffected by length of cut.

- The total tract starch digestibility (TTSD) was unaffected (P = 0.22) by length of cut.

The starch digestibility effect is interesting because many producers feel that a potential benefit of fine-chop corn silage is less reliance on kernel processing. But the authors concluded that “kernel processing or the interaction between kernel processing and length of cut are more important than length of cut alone with respect to TTSD.”

Some practical recommendations

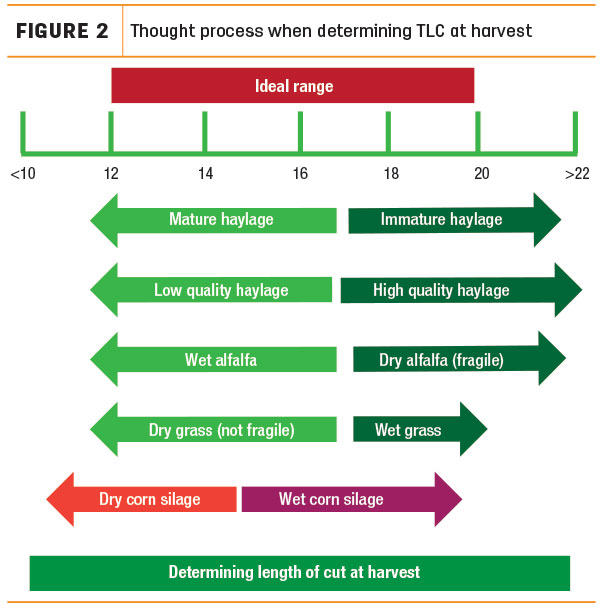

The ultimate goal for forage particle size is to produce a homogenous TMR that reduces sorting behaviour. We need enough physical structure to ensure adequate rumination through cud chewing and rumen contractions but not chopped so fine that rumen dysfunction may occur. A general recommendation would be to harvest forages at a TLC broadly between 10 and 22 millimetres (0.4 to 0.87 inch) but with an ideal range between 12 and 20 millimetres. This can vary due to species, maturity and DM differences of the crop being harvested. Figure 2 helps to illustrate some of the thought process when determining TLC at harvest.

Determining peNDF (physically effective NDF)

Ensuring that there is enough physically effective fibre in the diet is critical to ensure rumen health and dairy cow performance. Using the three-pan (four-compartment) PSPS (Penn State Particle Separator) is an effective tool to determine the peNDF value of the diet. The PSPS equipment contains three pans or sieves and a bottom tray (Photo 2).

Courtesy photo.

Courtesy photo. - Pan (sieve) No. 1 – represents the particles greater than 19 millimetres. These are the long particles that can potentially be sorted or lead to increased eating time. Recommendation: less than 5%.

- Pan (sieve) No. 2 – represents the particles greater than 8 millimetres. These particles are critical for optimum rumen function and should be representative of the TLC of the forage. Recommendation: greater than 50%.

- Pan (sieve) No. 3 – represents the particles greater than 4 millimetres. Feed particles found on this sieve will primarily be small forage pieces due to the variable distribution of particles within a forage. These particles do represent part of the effective fibre story, but they are easily digested by rapid microbial action and are the appropriate size to exit the rumen.

How do we determine peNDF?

The peNDF can be estimated by adding the amount of feed on the top three pans or sieves. (This amount represents the material 4 millimetres or greater.) This percentage should be in the range of 65% to 75%. This amount is multiplied by the total NDF content of the diet. The peNDF should be in the range of 20% to 23% of the DMI. But as noted earlier, research from the Miner Institute demonstrated that when the uNDF240 concentration is higher (based on a corn silage and dry timothy hay diet), reducing the peNDF resulted in an improved feed intake and performance.

Our concept of adequate particle size has changed dramatically over the last few years. Reducing particle size to an appropriate level for optimum rumen function, cud chewing and cow performance is critical. Perhaps “long is wrong,” but too short can also lead to health concerns. Applying the Goldilocks principle to particle size is a sound approach – not too long, not too short, but just right.