In box-type automated milking systems, rest feed is feed programmed for the cow to receive at the robot but not consumed for various reasons.

It could be because the cow did not have enough total visits to the robot, not enough time in the robot to consume the allotted feed, or the feed was not dense enough or palatable enough to be consumed efficiently.

Within this article, I will discuss how to avoid missing the nutrients we want individual cows to consume. That way, the cow can reach its genetic potential without the producer investing expensive ingredients in inefficient cows.

Technology has a way of changing the way we operate on today’s farms. Global positioning satellite systems have vastly changed the way we are able to manage our agronomy inputs. The ability to coordinate soil, weather, seeding and fertilizer rates allows today’s farmers to target soil nutrients and agronomic dollar resources.

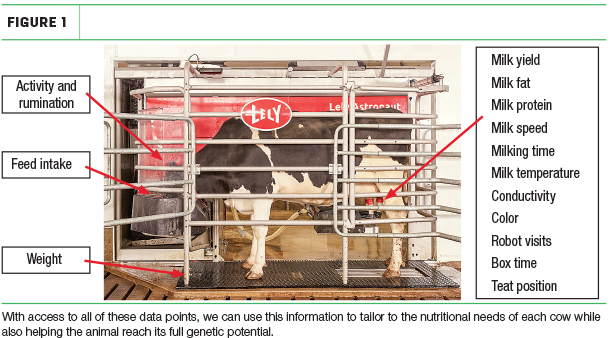

Robotically milked cows are tapping into those same resources, as we can now capture more than 120 points of data from each cow every day (Figure 1).

With access to all of these data points, we can use this information to tailor to the nutritional needs of each cow while also helping the animal reach its full genetic potential.

With access to all of these data points, we can use this information to tailor to the nutritional needs of each cow while also helping the animal reach its full genetic potential.

Cows naturally crave energy. We want to take advantage of that craving and entice the cow to the robot to harvest milk of its own free will. We want high-production, early lactation cows to milk three to five times a day and mid- to late-lactation cows to milk 1.8 to 2.5 times per day.

If a cow can consume enough energy to meet its craving at the bunk, the cow is less likely to visit the robot for milk harvest.

To avoid rest feed, we also need to make sure the cow has the opportunity to consume the targeted nutrients during robot visits while maintaining a meal size not too large to create a digestive upset. Given the variation in milking speed of individual cows, there needs to be enough time to consume the feed once the cow is there.

The density of the feed becomes a vital consideration in avoiding rest feed, as a cow can consume more of a dense product per minute in the robot than a fluffy, ground product. Typically, pelleted combination feeds or pelleted commodities are denser and can be consumed around a pound per minute. Ground feeds, which are not pelleted, are less dense and cannot be consumed as quickly (Figure 2).

They are messy and are more likely to hang up in the feeding system, thus not being delivered to the cow.

They are messy and are more likely to hang up in the feeding system, thus not being delivered to the cow.

If a cow can only consume 0.7 pound per minute and is in the box for only six-and-a-half minutes, that means the cow can only eat 4.5 pounds of feed during that visit, whereas the cow could eat 6.5 pounds in that same amount of time if the feed were denser and could be consumed more efficiently.

There is no sense in designing a feed program that asks the cow to consume a greater amount of feed than it can comfortably consume in the robot. For example, if a high-production cow is coming to the robot three times per day and can only consume 6 pounds on any one visit, there is no purpose in asking the cow to eat 20 pounds per day (3 x 6 = 18).

The other 2 pounds of feed would become rest feed. However, if we can get the cow to come to the robot every six hours, we can split that 20 pounds into 5-pound increments, and the cow can consume the appropriate total amount in a meal size healthier for its rumen.

In this manner, we can more accurately deliver the targeted nutrients the high-production cow gets and hold back expensive nutrients from mid- and late-lactation cows where overfeeding can lead to over-conditioning that will have to be dealt with at the next freshening.

The extra milking is also more likely to capture the cow’s genetic potential of higher outputs of volume and components. Yes, you could supply that other 2 pounds of feed over at the bunk in the partially mixed ration, but then low-production cows would get those nutrients as well, and the high-production cow would be less likely to have the extra milk harvest and realize its genetic potential.

Robotic systems have the capability of controlling:

1. Meal size per visit

2. Rate of feed delivery per minute

3. Rate of feed increase or decrease in amount fed from day to day depending on milk outputs

To avoid rest feed, set the meal size maximum to a level that will not cause too much of a drop in rumen pH and will encourage the high-production cow to come back to the robot for the next milking. Ensure the density and form of the feed is one the cow can consume readily, and match up the feed delivery speed with the amount of time the cow is in the robot.

Also, use the safeguards built into the system to make certain feed delivery does not ramp up too quickly during the time after freshening or take feed away too quickly if the cow is having a bad day.

Matching these management tools along with the individual outputs of the cow makes targeting nutrients and feed dollar resources wholly possible. Coordinating these parameters takes great care and is a balancing act that requires slightly more attention.

But with that attention comes the ability to minimize rest feed, have the cow consume the vital nutrients necessary to reach its genetic potential and maximize income over feed costs. ![]()

-

Tom Sauerman

- Senior Farm Management - Support Adviser

- Lely

- Email Tom Sauerman