2020 was a year like no other for many reasons, and dairy producers were forced to look more closely at input costs due to the drastic volatility seen in the commodity markets.

When evaluating input costs, feed often comes under the microscope first, as it typically accounts for over 50% of a dairy operation’s cost of production. Oftentimes the knee-jerk reaction is to simply cut costs, whether that be from a purchased or total cost standpoint, an ingredient or nutrient standpoint, or from an additive standpoint.

The results of these snap decisions are sometimes a loss of production which outweighs the cost-cutting in the first place. However, taking the time to truly evaluate costs through the lens of setting a SMART goal may help dairy producers to evaluate feed costs, or preferably total input costs, in a way that can be a benefit to their bottom line.

How you set goals for your dairy operation can be the difference between achieving them or not. This year, make sure all of your goals are SMART:

- Specific. What exactly do you want to accomplish? Then identify the who, when, where and why.

- Measurable. How will you know you’ve accomplished it?

- Attainable. Is it in your sphere of control?

- Relevant. Will this goal have a positive impact on your business? Is it worth the time and resources to achieve it?

- Timely. When will you accomplish it? Do you have the time to focus on it?

Due to the sharp increase in commodity prices in the latter portion of 2020 (compounded by drought in some areas), many dairy producers will be in a position where purchased feed costs were significantly higher and revenue did not increase at the same rate in the past year. Therefore, the obvious business goal is to evaluate areas to improve profitability. While this is an excellent overarching goal, it needs to be broken down into SMART actionable goals and shared with your management team to keep everyone accountable. Let’s run through a few examples of how we can put SMART goal-setting into practice.

Example 1

Goal: Reduce heifer costs

SMART Goal: Reduce heifer inventory from 120% to 108% by December 2021 by selling 1% per month

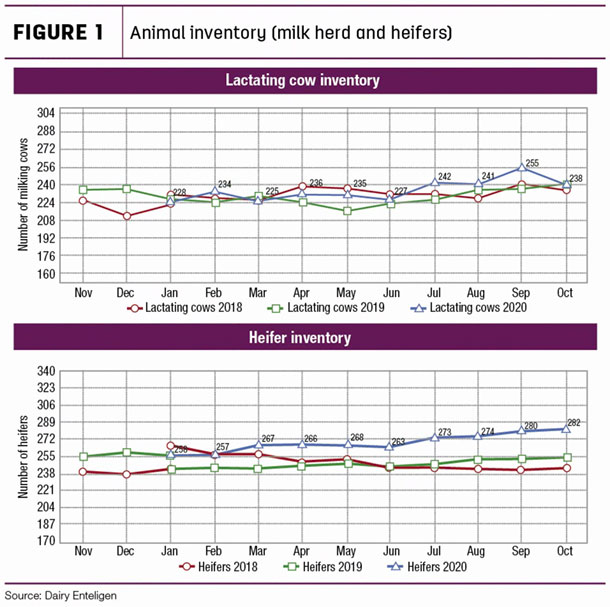

In Figure 1, we see a three-year snapshot of lactating cow inventory plotted on the top graph and heifer inventory plotted on the bottom graph.

Over the course of 2020, heifer inventory has steadily increased to the point where, based on the herd’s culling rate, age at first calving and heifer non-completion rate, they have almost 30% more heifers than needed. Therefore, when looking at this data, the real question that needs to be asked is not “Are you paying too much per tonne of feed?” but rather “Are you raising too many heifers?” For this, and many other dairy operations, it is the latter, and implementing a specific goal to address that issue will have positive impacts beyond reducing basic heifer inputs (less overcrowding leading to fewer health issues, better gains and improved lifetime productivity).

Example 2

Goal: Reduce lactating cow feed costs

SMART Goal 2: Review cost-to-benefit ratio of additives in lactating cow program in February (annually)

This is a SMART goal that should be reviewed annually, not only for the lactating herd but for each group of animals that are part of the dairy operation. Is the additive being targeted at the correct group of animals? Was it added to combat a specific issue, and did you get the expected response? Have other changes been implemented since then that could warrant the removal of the additive now? Is there a different additive that may be a better fit for your herd now due to changes in facilities or feeding programs? What are the possible short- or long-term implications of removing key additives?

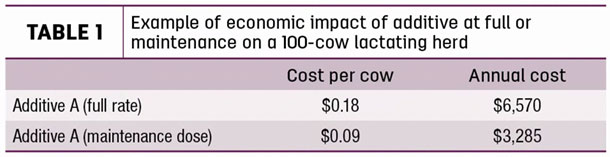

An excellent example of why this SMART goal should be done on an annual basis is to consider the usage of products used during years when mycotoxin levels are high. The harvest of 2018 brought with it record-breaking mycotoxin levels in some parts of the country and, as a result, most producers incorporated additives into their feeding programs to mitigate the impact of mycotoxins in their herds. It is critical that the following year the use of the additive be evaluated – can it be removed entirely or, based on the new crop year, should a maintenance dose be fed? Table 1 shows that a careful evaluation of even a single additive for your herd could result in a significant savings.

Example 3

Goal: Reduce purchased grain costs

SMART Goal 3: Improve forage quality to optimize purchased nutrients

Many times when producers are lowering purchased grain costs, we see them focusing on reducing the cost of certain ingredients in their diet. An example would be purchasing commodities in large bulk loads in order to get the best deal at the time or switching between soybean meal and canola meal depending on the price per tonne at the time. Although both these strategies warrant consideration and may provide small cost savings over the course of a year, taking a step back and asking the question “What nutrients am I purchasing for my cows?” versus asking “What ingredient is the best buy currently?” will bring a new perspective.

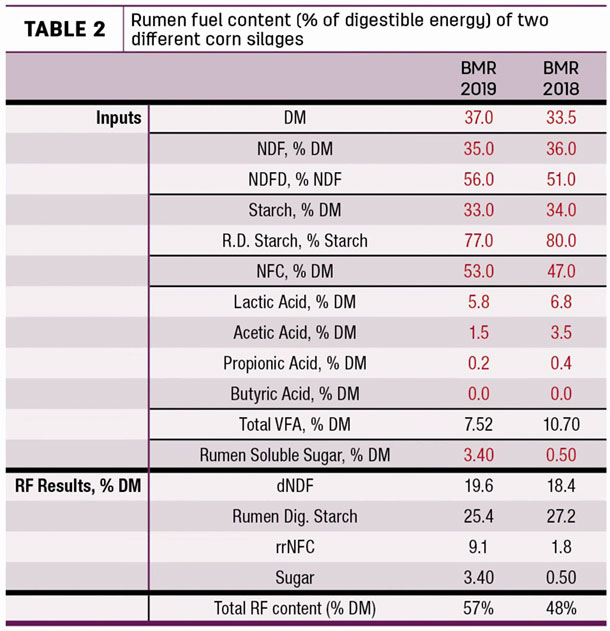

When evaluating rations for dairy cattle, it is important to remember that cows have a requirement for nutrients, not ingredients. Cows require certain levels of amino acids, energy, and vitamins and minerals depending on their stage of production. So while switching from feeding soybean meal to canola meal or vice versa may make sense on a dollars per percentage of crude protein basis at a certain time, it may not make sense for every ration scenario due to differences in amino acids and energy levels. Instead, focusing on improving forages by working with your management team to identify areas of improvement all the way from planting to crop fertility, to harvest, to ensiling and to feedout to maximize the amount of digestible nutrients per tonne of forage to “fuel the rumen” can yield significant savings on purchased nutrients. Remember that forage quality is more than just protein (Table 2) and that increasing digestible energy on all forages is the goal.

Taking the time to create SMART goals for your dairy operation using solid data from your own operation and seeking input from the entire management team can help to bring in new perspectives when setting goals for the future direction of your operation. This will not only help everyone stay focused on the key areas that have been identified, but there is also a much better chance these goals will be realized when names, actions and timelines are applied. Setting SMART goals, evaluating progress, modifying as needed and celebrating with the team the achievement of these goals are all critical parts of successful business planning.