In addition, our milk quality can be known within a couple days and for some on-farm technologies, within minutes.

When looking into adopting a new technology on your farm, it is always good to identify how it will help you achieve your goals.

A veterinarian can be a useful resource and a valuable person on your management team when making changes that will affect your herd.

Together, look at where are you at now by comparing your own herd records to previous years, other producers in the area or provincial averages by interpreting DHI records.

And then ask yourself: “Where do I want to be, and how can I achieve that goal?”

(Click here or on the image above to view it at full size in a new window.)

Heegstee Farms followed that process prior to adopting the use of Herd Navigator, one of many new on-farm technologies launched in the last decade.

Originated and developed in Denmark by Lattec and distributed by DeLaval, this technology is unique in that it is an on-farm and online serial automated milk sampling laboratory that will evaluate individual cows for mastitis (LDH – lactate dehydrogenase), reproduction (progesterone), metabolic disorders (BHB – beta-hydroxybutyrate) and feed protein (urea) by analyzing milk using dry stick technology. This helps the farm identify individual cows in need of special attention.

Heegstee Farms, owned and operated by Sjoerd and Rinske Heeg, along with their son, Sytse, and his wife, Anita, is one of four farms in Canada to be using the technology along with its two robotic milking systems.

Together with its herd veterinarian, Dr. Glen Blier, the Heeg family has summarized some of its experiences with Herd Navigator over the past year in the following paragraphs.

Progesterone serial testing

Progesterone levels, recorded in ng (nanograms per millilitre), are obtained via online progesterone serial testing. A typical progesterone graph would show a cow’s progesterone level rising and falling within an approximate 21-day cycle.

This allows the producer to inseminate as her progesterone levels drop. Due to the unique online serial testing in this system, two days prior to a cow’s physical heat signs a heat detection alarm is given, allowing the producer to have a better probability to successfully breed her.

In terms of a silent heat – where activity is absent – progesterone levels may still show a peak and valley to allow for an insemination. With Blier’s assistance, Heegstee Farms is able to look ”inside” of the cow and see precisely where she is in her cycle and reduce the guesswork.

With this level of precision, through the system finding 95 percent of heats, Heegstee Farms has increased its pregnancy rate by 10 percent (calculated by DC305).

To handle cows that show up as anestrous or have a luteal or follicular cyst, as determined by her progesterone levels, Heegstee Farms and Blier created appropriate standard operating procedures (SOPs) that can be easily followed.

Due to this, specific drugs can be precisely administered to stimulate cycling or remove the cysts. It reduces guesswork or blindly starting an Ovsynch in the hopes that it will alleviate the problem.

This has resulted in lower drug costs in comparison to the previous year. There is no question that both Heegstee Farms and Blier feel they are making better treatment decisions with this individual and daily information than was achieved with conventional rectal palpation.

Continual high progesterone levels confirm that a pregnancy is reached, thus reducing the need to palpate cows, which additionally reduces the costs related to reproduction.

With the cow now pregnant, her progesterone levels will not drop and, therefore, testing is terminated at 55 days past her last insemination. If no drop in progesterone is seen, the system will automatically determine her “pregnant” at 35 days.

In fact, it will change her status internally starting at day 24 if no drop in progesterone is seen – but does not present the change in status to the farmer until day 35 due to the increased risk of an embryonic loss.

From Blier’s perspective, this presented an opportunity to change his role on the farm. Similarly to when veterinarians changed their role from only treating sick animals and moved toward “herd health,” where reproduction became more of the focus; this is an opportunity to move forward again.

By allowing this system to collect and do some preliminary interpretation of data, the new veterinary role can be more focused on true overall herd health through co-creating and altering SOPs as needed. It’s very short-sighted to feel that if there are no longer rectal palpations to be performed that the veterinary role is no longer needed.

Ketosis

The system starts this sampling process on day 3 post-calving and identifies ketosis cases very early such that Blier’s suggested treatments are usually limited to oral administration of glycol with a short duration of treatment, thus reducing drug costs.

Interestingly, the system will show either a decrease in ketones followed by a rise in milk or a continued rise in ketones. Based on the system’s feedback, Blier suggests how treatments can be altered.

This will help reduce the potential need for surgery for displaced abomasums as a possible result of ketosis.

In addition, ketosis has a negative influence on reproduction in dairy cattle by delaying the number of days until she ovulates good-quality eggs. Due to the automatic sampling from day 3, the need to chase after a fresh cow to perform a test is eliminated. The SOPs are therefore based on system alarms, not visual signs or the use of olfactory.

The single-most frustrating problem on a farm is finding the cow that needs treatment early and easily. From Blier’s perspective, this is the best way to help prevent post-partum disease.

When these issues are looked after early, more milk is put in the tank. At Heegstee Farms, it has resulted in fewer displaced abomasums, a decrease in ketosis treatment costs and, as the DHI results show, a more consistent and higher standard milk average.

Udder health

The composite sample is tested for LDH, which is released when cells in the udder are damaged after infection. This allows for earlier detection of mastitis when no visual signs are shown by the cow by obtaining a milk sample.

In contrast, in the per-acute toxic cases where production drops to a negligible amount, detection of LDH becomes more difficult. In less severe gram-negative cases (E. coli, Klebsiella) and gram-positive cases (Strep or Staph infections), the levels usually rise 48 to 72 hours prior to the onset of clinical signs, allowing Heegstee Farms to proceed with treatments early and reducing milk yield losses that may have occurred with later treatment.

As these less severe (subclinical) cases accounted for 90 percent of the mastitis in this herd, it became a very useful tool in planning and implementing treatment protocols.

The system does not identify the infected quarter. To determine which quarter to sample, Heegstee Farms uses the Delpro MDI (combination of conductivity and colour change for each quarter) and DeLaval Direct Cell Counter (DCC).

The lead time between alerts and clinical signs gives an opportunity to culture and treat each case with a precise treatment based on the organism present.

For this project Heegstee Farms uses the Maritime Quality Milk treatment decision kit as an easy-to-use on-farm culture system. Additional sub-culturing is done on the gram-positive cases to determine if Staph. aureus was the causative agent.

This new process and protocol has resulted in improved bulk tank SCC of an already good SCC average. Drug costs have also lowered due to the ability to target each mastitis case specifically on the organism found.

Urea

Although the urea sampling and recording is currently the least-used item of this system at Heegstee Farms, it does reflect the energy and protein balance of the feed ration.

Samples are taken and alarms are based on a seven-day rolling average. Feed changes can be made and the farm can set a specific lower and upper limit for the urea alarms.

Along with new technology comes a learning curve. For both Heegstee Farms and Blier, this has meant learning to trust this system, understanding the graphs and alerts and creating SOPs specifically for the herd.

After working with it for nearly one year, both Blier and Heegstee Farms feel that a comfort has been reached with the system’s decisions and follow-through of the created SOPs. PD

Glen Blier is a veterinarian with the New Hamburg Veterinary Clinic.

PHOTOS

TOP: Heegstee Farms’ veterinarian, Dr. Glen Blier (left) and one of the farm’s owners, Sytse Heeg (right) review data provided by the Herd Navigator system. The Heeg family and Blier have worked together to build farm protocols based on test data from this new system.

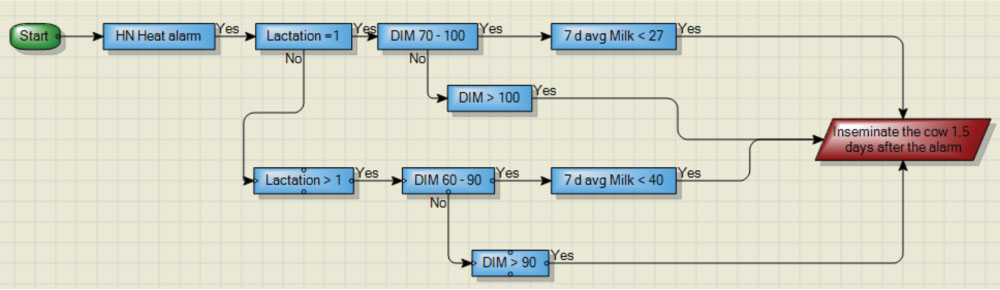

BOTTOM: Heegstee Farms and its herd veterinarian Dr. Glen Blier have developed protocols based on Herd Navigator alarms similar to the example insemination protocol shown here. These protocols can be written into the software so when an alarm is triggered an automatic action is generated and displayed on a list of cows needing attention.

- Anita Heeg

- Heegstee Farms

- Dairy Specialist – Alltech